High Quality Rapid Prototypes, Rapid Injection Moldings and Rapid Parts

Over 3000 companies in 50 countries use HLH’s high quality manufacturing solutions to reduce costs and time to market

Start Your Free Project Review

At HLH Prototypes we specialise in Rapid Prototype Manufacturing Services, to customers across the world. Our 3D Printing Prototypes, CNC & Injection Moulding services, providing everything from prototype to production manufacturing solutions.

In the fast-paced world of new product innovation, you need a partner you can rely on for rapid injection molding, rapid prototypes, and low-volume production. We supply prototype manufacturing services that can deliver with the speed and quality your project deserves.

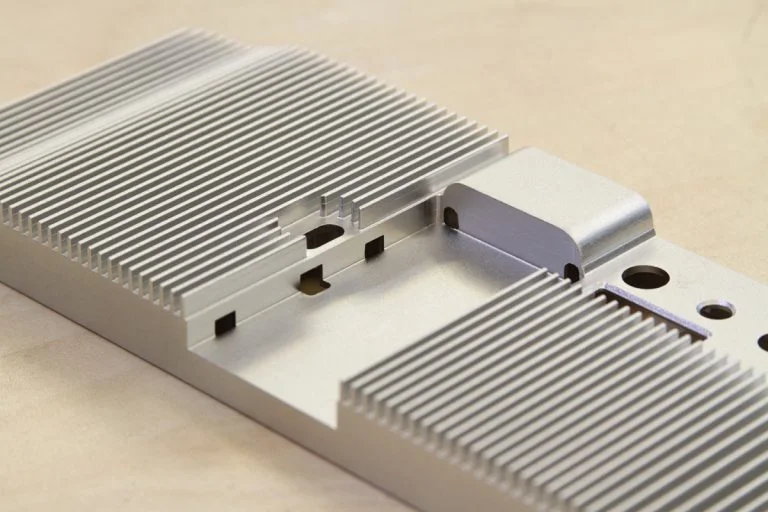

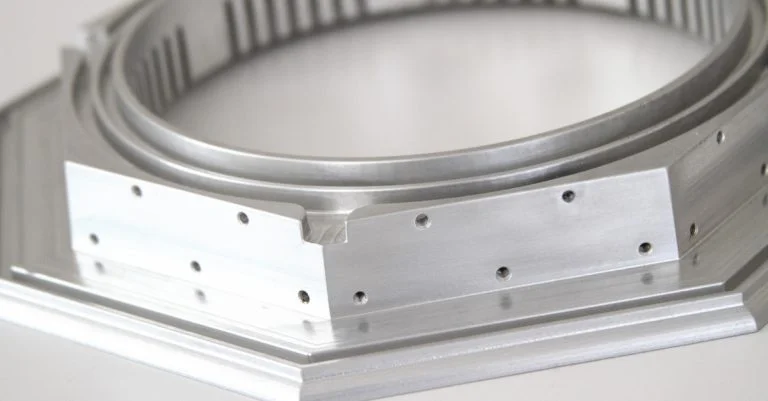

Rapid CNC Machining

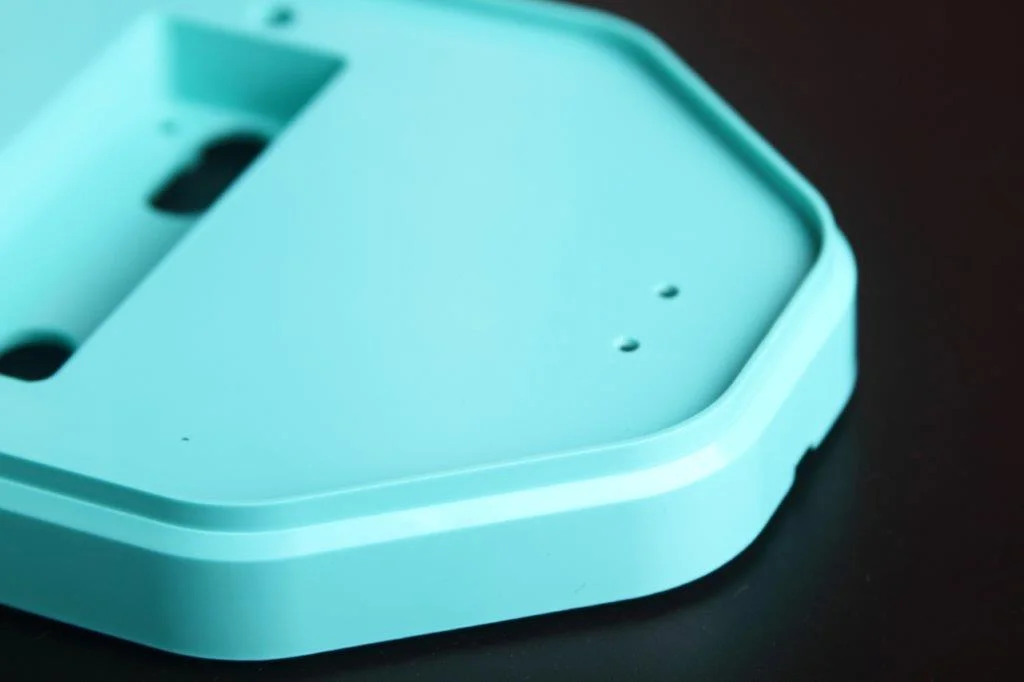

Rapid Prototypes & 3D Printing

Rapid Injection Molding & Tooling

Rapid Sheet Metal Work

Rapid Die Casting

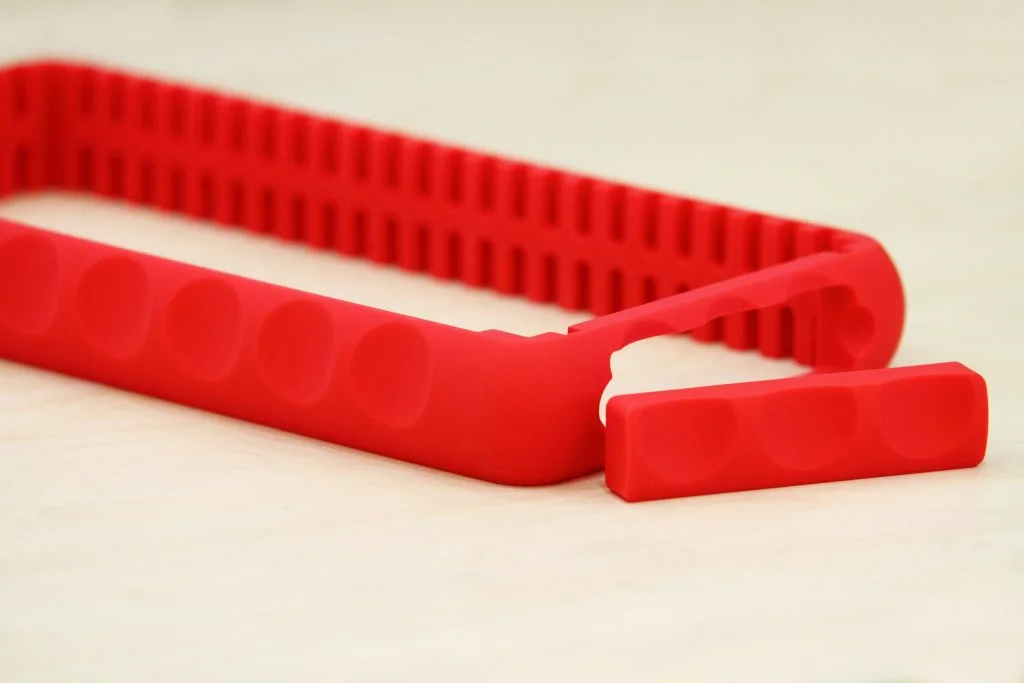

Rapid Vacuum Casting (Urethane Casting)

Rapid Carbon Fiber

Please contact us here for more information.

At HLH, we make things for you. Rapid products and parts delivered fast. Rapid tooling that delivers more parts than you are used to. First class prototypes that look like production parts. Fully functional parts that act like production parts. Flexible project solutions that fit your specific project requirements. Our MOQ starts at 1 for prototypes and typically goes up to 100,000 parts (plastic, metal, composites), anywhere in this range is what we would consider low-volume manufacturing.

Follow us on Facebook or LinkedIn for daily tips, advice, trends, and opinions on rapid manufacturing. For fast parts, start your free project review here.

HLH work with leading automotive brands both in China and around the world. We have delivered some prototypes and parts for some of the highest profile and most desirable vehicles on the road. We work with...

We offer tailored solutions to the aerospace and UAV markets enabling them to rapidly innovate new solutions. Our range of tailored services, everything from prototyping through to low/mid volume production...

HLH have been building prototypes and parts for the consumer products industry for years. We already work with some of the worlds leading names big and small, companies like Whirlpool and Oculus...

We enable you to focus on what is important for your team and your clients by offering a range of tailored solutions to the industrial and energy industries. We work with some of the worlds largest companies...

The medical industry needs high quality, dependable and safe parts and products so they can deliver healthier and happier lives to all. At HLH we have been working with medical device manufacturers large and small...

Robotics and automation are two of the fastest growing industries globally and there are exciting developments and challenges to be faced every day. HLH work with some of the worlds leading names, companies...

The communications industry is everywhere, and we rely on it evermore throughout our daily lives. With the emergence of IoT and smart devices the depth to which it impacts our lives grows even deeper...

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet. You are the backbone of our business too, HLH work with product designers the world...