How to Choose the Best Prototype Manufacturer

How to Choose the Best Prototype Manufacturer

Choosing the right prototype manufacturer is an important step in the journey of bringing a product from concept to market. Whether you are an entrepreneur working on a groundbreaking invention or an established company developing a new product line, finding the right prototype manufacturer that meets your specific needs can be a game-changer.

The right prototype manufacturer not only brings your ideas to life but also influences the quality, cost, and timeline of your project. This blog aims to guide you through the process of identifying and selecting the best prototype manufacturer for your unique project, ensuring a smooth and successful transition from concept to reality.

With a focus on understanding industry standards, evaluating technical expertise, and considering cost-effectiveness, we will delve into what makes a prototype manufacturer stand out in this competitive field.

What is a Prototype Manufacturer

A prototype manufacturer is a company or facility that turns design concepts into physical models or prototypes. These prototypes are essential in the product development process, allowing designers and engineers to test and improve their ideas before full-scale production.

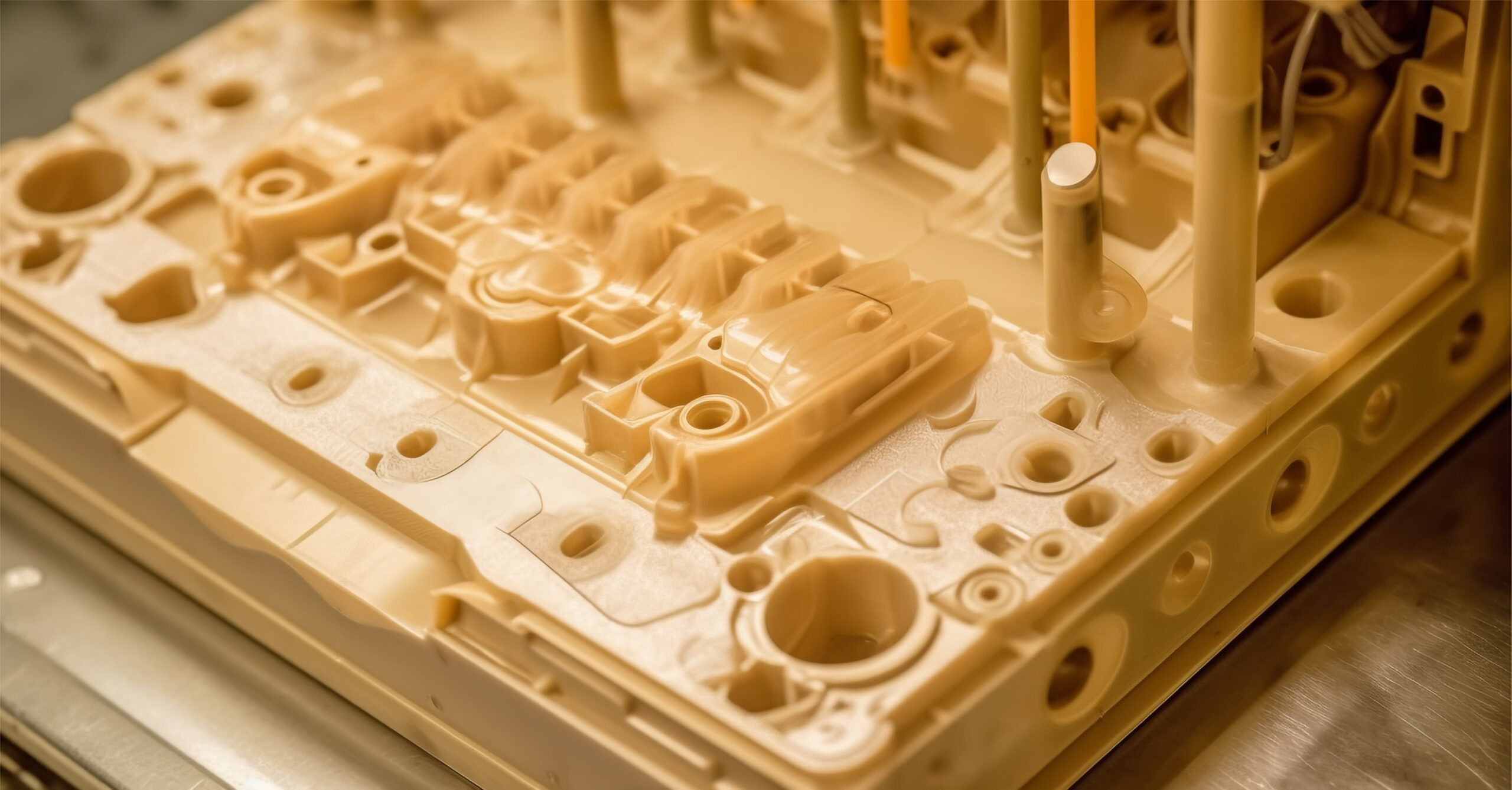

There are different methods and materials used in prototype manufacturing. These range from traditional methods like machining to modern techniques like 3D printing. The choice of method depends on factors like the complexity of the design, the materials needed, and the level of detail required in the prototype.

The role of a prototype manufacturer is not just to create a physical product. They also offer expertise in design and engineering, helping to identify and fix potential issues in the prototype. This process saves time and money by ensuring that the design is as refined as possible before mass production begins.

Choosing the right prototype manufacturer is vital. The quality of the prototype can affect the entire product development process, from design to final production.

Why Choose HLH as Your Prototype Manufacturer?

HLH Prototypes stands out as a leading choice for prototype manufacturing due to its affordable pricing, scalability and comprehensive range of services that cater to diverse prototyping needs. Here’s why choosing HLH can be beneficial for your project:

- CNC Machining Services: HLH offers state-of-the-art CNC machining services, which are ideal for creating precise and high-quality prototypes. This method is perfect for both metal and plastic parts and is highly versatile for different design requirements. CNC machining with HLH ensures accuracy and consistency in your prototypes, which is crucial for testing and validation.

- 3D Printing Prototyping: Embracing the latest in technological advancements, HLH provides exceptional 3D printing services. This method is ideal for rapid prototyping, allowing for the quick turnaround of complex designs that might be difficult or impossible to achieve through traditional manufacturing methods. 3D printing with HLH is a cost-effective way to produce prototypes, especially for intricate designs and small batch runs.

- Rapid Injection Moulding: For projects requiring high-quality plastic parts, HLH’s rapid injection moulding service is the go-to option. This service is particularly valuable for simulating the properties and appearance of the final manufactured product. It’s an excellent way for testing materials and designs in a close-to-production context, offering insights into the final product’s look, feel, and function.

By offering these diverse and advanced prototyping services, HLH positions itself as a versatile and reliable prototype manufacturer. Whether you need a single prototype or a series of models for comprehensive testing, HLH’s expertise and technology can accommodate your specific requirements, ensuring your project progresses smoothly from concept to final product.

Evaluating Prototype Quality and Accuracy

When selecting a prototype manufacturer, evaluating the quality and accuracy of their prototypes is essential. The quality of a prototype can significantly impact your project’s development, testing, and final production stages. Here’s what to consider when assessing prototype quality and accuracy:

- Material Quality: The materials used in your prototype should closely match or simulate the properties of those intended for the final product. Check for material durability, texture, and weight. High-quality materials ensure that the prototype effectively represents the final product, especially in functionality and aesthetic aspects.

- Dimensional Accuracy: One of the most critical factors is how accurately the prototype dimensions reflect the original design specifications. Dimensional accuracy is vital for fitting and functional testing. Small deviations can lead to significant issues in the later stages of product development. Ensure that the prototype manufacturer has a robust quality control process to maintain high precision.

- Finish and Aesthetics: The finish of the prototype is another important aspect. It should resemble the final product as closely as possible, especially if the prototype is used for presentations or consumer testing. This includes surface texture, color, and any other aesthetic details. A good finish not only makes the prototype more representative of the final product but also indicates the manufacturer’s attention to detail.

- Structural Integrity and Functionality: Evaluate how well the prototype withstands stress, load, or any other operational conditions it’s likely to encounter in real-world scenarios. Functional testing helps in identifying potential weaknesses or design flaws.

- Consistency Across Multiple Prototypes: If multiple prototypes are produced, check for consistency among them. Consistency indicates reliable and controlled manufacturing processes, which is crucial for scaling production in the future.

- Feedback and Iteration Process: Finally, consider the prototype manufacturer’s responsiveness to feedback and their ability to iterate on the design. A manufacturer that provides constructive feedback and can efficiently incorporate changes plays a vital role in achieving the desired prototype quality.

Evaluating these aspects of prototype quality and accuracy will help you choose a manufacturer capable of delivering prototypes that meet your project’s specific requirements. Remember, a high-quality prototype not only provides a reliable basis for further development but also saves time and resources by reducing the need for multiple iterations.

By setting clear benchmarks for quality and accuracy, you can ensure that your prototype is a true representation of your final vision, paving the way for a successful product launch.

Cost Considerations and Budgeting

Addressing the financial aspect of prototype manufacturing is crucial in the development process. The cost of creating a prototype can vary significantly based on several factors. Understanding these factors will help you budget more effectively and make informed decisions. Here are the key cost considerations to keep in mind:

Material Choice:

The type of materials used for your prototype can have a significant impact on cost. More expensive materials may offer better quality or more accurate simulation of the final product, but they will increase the prototype’s cost. Weigh the benefits of high-end materials against their cost, especially if a less expensive alternative can still meet your needs.

Manufacturing Technique:

Different manufacturing techniques come with varying cost implications. For instance, 3D printing might be more cost-effective for complex, custom designs, while CNC machining might be more economical for larger quantities or simpler designs. Consider the most suitable technique for your prototype, balancing cost with the required precision and quality.

Complexity of the Design:

The more complex your prototype’s design, the more time and resources it will require, leading to higher costs. Simplifying the design where possible without compromising essential features can help manage expenses.

Quantity of Prototypes:

The number of prototypes you need will also affect the cost. Producing several prototypes can be more cost-effective per unit, but it increases the overall budget. Determine the minimum number of prototypes needed for effective testing and presentation.

Turnaround Time:

Fast turnaround times can incur additional costs. If you require a prototype quickly, be prepared to pay a premium. Planning ahead and allowing more time for prototype development can help reduce costs.

Additional Features and Customization:

Any extra features or customization, like special finishes or unique materials, will add to the cost. Evaluate the necessity of these additions in relation to their impact on the budget.

Revisions and Iterations: Factor in the potential need for revisions. The first prototype often isn’t perfect, and additional iterations can increase the project’s cost.

When budgeting for a prototype, consider getting quotes from multiple manufacturers to compare costs. Also, be transparent with your manufacturer about your budget constraints. They may offer solutions or alternatives that fit your financial parameters. By carefully considering these cost factors, you can budget more effectively for your prototype, ensuring that the development process remains financially viable.

How to Collaborate Effectively with Your Manufacturer

Effective collaboration with your prototype manufacturer is key to the success of your project. When working with HLH, clear and consistent communication is essential. Make sure to articulate your project requirements, expectations, and timelines from the outset. Our team values transparent communication, which ensures that your ideas are fully understood and accurately realized.

Providing us with detailed information, such as technical drawings and material specifications, will help them understand your project better and deliver more precise results. Remember that the prototyping process is often iterative. HLH encourages active client involvement, so regular feedback and discussions about the prototype’s progress are crucial.

Being open to suggestions from our experienced team can also be beneficial. Our expertise may offer valuable insights that could enhance your prototype or make the process more cost-effective. It’s also important to trust their expertise and respect the timelines they provide.

We at HLH combine technical knowledge with efficient project management to ensure projects are completed on time without compromising quality.

Sustainability and Eco-Friendly Practices

In today’s world, sustainability is a critical consideration in manufacturing. We recognize the importance of eco-friendly practices in prototype manufacturing. Our team is committed to reducing environmental impact through various initiatives.

This includes using sustainable materials wherever possible and implementing energy-efficient manufacturing processes.

We at HLH also focus on waste reduction strategies. By optimizing design and manufacturing processes, they minimize material wastage. Our approach not only benefits the environment but also helps in reducing the overall cost of the prototyping process.

By choosing HLH as your prototype manufacturer, you’re partnering with a company that not only values the quality and precision of its work but also takes responsibility for its environmental impact. Our commitment to sustainability is a testament to our dedication to being a forward-thinking and responsible manufacturer.