Consider Fabricating Multiple Prototypes Simultaneously

Time is money and speed to market is a key factor to the success of any new product. Two big reasons why you should consider fabricating multiple prototypes simultaneously. You have your design all worked out, and it’s perfect…to you. The problem is you are not the buyer of your product and a retail buyer or the end consumer of your product may want your product, but in a different configuration. Consider these factors below when you are at the Prototype phase of your project.

Design Variations –  Having multiple prototypes, slightly varied iterations of your design early on will help you to overcome any negative feedback you may receive on your design. For example the design variation could be different feature sets on the same product that can then be test tested with focus groups. The feedback from these sessions is incredibly valuable in helping you figure out the final design for the market, focus groups run with multiple products will yield better feedback. A focus group can help identify features that can possibly be removed, saving money, to help you hit a better retail price point. A focus group may also give you feedback to add a feature that will really make your product stand out above your competition. Give your focus groups plenty to talk about with multiple design iterations.

Size & Feel – Another reason to test multiple prototypes early on is to try the same design in slightly different sizes and finishes. If your product is a tactile product that needs to be handled a lot the size of your product could make or break your idea. Also, you may discover that a mini or larger size of your product is determined to be the better version of your product or that you can extend your idea into several products with different sizing. Feel is the finish that you put on your product, polished or textured finish, rubber finish or painted finish. There are so many ways that one can finish a product. What you have designed may look good on paper but in a real world application you may find a different finish is the better option. Why wait to find out? The answer is don’t, try a couple of different finishes at the same time.

Material – You may think your product should be made from metal or plastic, but don’t limit yourself to one option. Try at least two different materials so you can evaluate the pros and cons of each side by side. For example you may think your product needs to be made out of metal for strength but there are many strong plastic materials that may do the trick. Also, you may find that even if your product should be made in plastic (to hit the price point you need) that there may be a premium metal version of your product that some segments of the market will appreciate and be happy to pay a higher price for. The point is don’t limit yourself, think outside the box, test outside the box.

Strength – The more RAW material you need for your product the more expensive it will be. There is a fine line between making a product strong and making a product cost effective. Making several prototypes at the same time can help you determine the right wall thickness of your product or identify a specific part of your design that may need beefing up in order to give it added strength. Having different versions to evaluate that are lighter or more robust will help you make final design decisions faster. Whatever you end up doing at least consider making 1 prototype that is stronger than needed for the simple reason that someone will end up breaking some of your prototypes. So at least have one stronger prototype as your back up that you can show to investors or take to sales meetings.

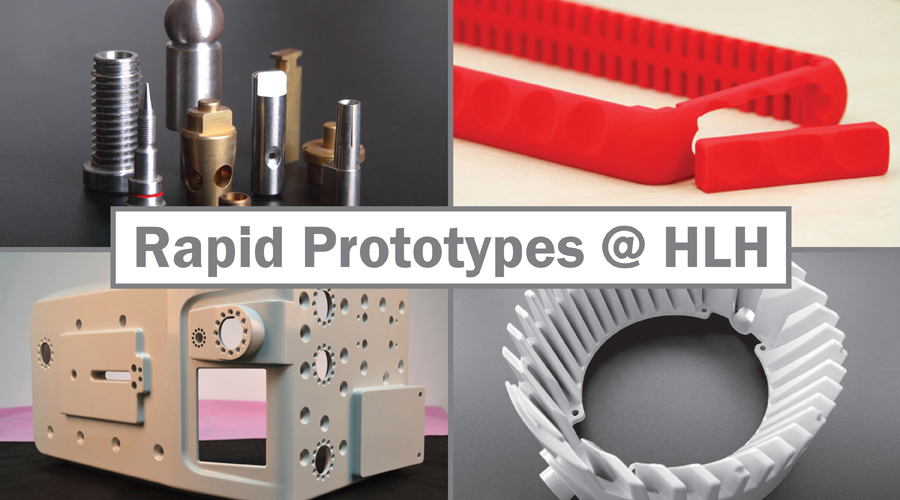

Prototype Fabrication Process – 3D Printing and CNC Machining are two examples of rapid prototype manufacturing solutions. 3D can be a great way for a quick turnaround prototype part. It can give you a real quick look at your design for a quick verification of what you are seeing on paper or on your computer. But 3D often lacks the robustness that one finds in CNC Machining, so if your product needs any strength at all CNC may be the better fabrication process for your prototype. That said, consider making 1 prototype from 3D Printing and 1 from CNC Machining so you can understand the pros and cons of each process. Doing so early will help you to understand what fabrication process is the best solution for further prototype needs, and it will help you understand if either fabrication process could work for you as a low volume production solution.

Making multiple prototypes simultaneously may sound expensive but in reality it may be the cheapest thing you ever do. Closing off designs and getting to market faster is the best way to make any project cost less and succeed, multiple prototypes, for earlier results, will ultimately save you money.

To start your rapid prototypes today email FreeQuote@HLHPrototypes.com.