Why is CNC Machining Better than 3D Printing for Prototypes?

Advances in technology have made it possible for manufacturing companies to have options when creating prototype parts and tools for a wide range of industries. The process is highly dependent on the design, required material and purpose of the sample but in some cases there are techniques that stand above the rest for durability, functionality and cost.

Some of the most common methods on the market include rapid injection, CNC prototyping or machining and 3D printing and while all of these options are viable in their own right, they are not created equal. The majority of companies that partner with prototyping manufacturers are looking for fast turnaround times and quality products to be used for testing in trade fairs, presentations and design run-throughs. The purpose of a prototype is to ensure that the overall design is solid before spending the money on bulk quantity production.

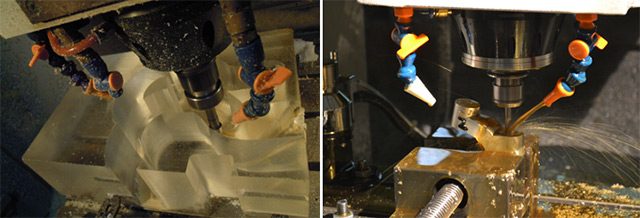

If you are looking for a rapid prototyping process that will create a functional and durable product then you want CNC machining as your top choice. This technique works with a variety of metals and plastics so that businesses can choose the right kind of material without being limited and the machine’s precision is exact with every cut. 3D printing is also able to deliver projects on a rapid timetable but the limitation on materials can affect the prototype’s functional ability. This aspect by itself is one of the reasons why CNC machining is preferred above 3D printing and can be used for production runs on low or high volume quantity requests. It is also cost efficient since the design is fed into a computer program which coordinates with the machine executing every cut that is made on the material. The finishing and inspection process are performed before the product is sent to the customer to ensure that it meets all the necessary standards and specifications.

While every method has a purpose and can be utilized in different situations, the hallmark of a professional manufacturer is combining the right method with each project based on what is best for the customer. Rapid prototyping CNC is an exact science and must be accomplished with precision and accuracy to be truly successful. So make sure your vendor is utilizing the right technique for your project!