Start making today - get in touch for free quote and project review

Carbon Fiber Manufacturing for Aerospace & Automotive Sectors

Carbon fiber parts are revolutionizing many industries and their weight saving advantages are being used extensively. For situations where less weight equates to better performance; Carbon Fibre parts are a must.

We at HLH manufacture tooling and carbon fibre parts for many industries, from Aerospace & UAV, to automotive & sports products. We have in-depth experience designing and manufacturing of composites & specialise in CFRP products, such as autoclave, RTM, press, and SMC molding.

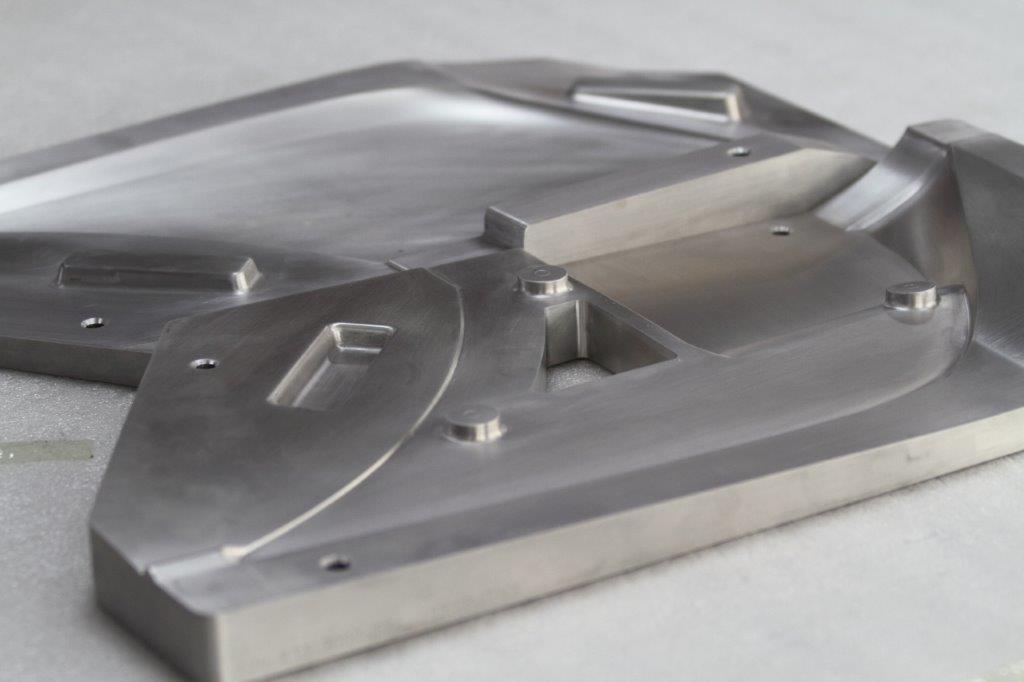

How It Works – Much of the process is still manual. A mold tool is manufactured often from aluminium or steel depending on the quantity of parts required. The carbon fiber prepreg sheets are then manually laid by skilled technicians.

To start your free project review, contact our team today.

Testimonials

Advantages of Carbon Fibre Molding

- High strength to weight ratio

- Weight saving applications

- Good surface finish

- Complex part geometry

- Great for low volumes

Used for

Automotive, aerospace, applications where light weight but high strength parts are required, replacing sheet metal parts

Start Your Free Project Review

Carbon Fiber Tips

Carbon fiber is all about reducing weight while maintaining strength. Due to the high costs of the current processes for manufacturing carbon fiber parts it is important to understand the limitations and what you can do to bring costs down.

Underlying layers are one area you can reduce costs if your end use allows. The distinctive 3K weave pattern is a big draw for choosing carbon fiber, but these are more expensive than UD sheets or fiberglass which can be used as the bottom layers with a 3K top sheet.

To learn more talk to our rapid manufacturing team today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...