7 Reasons To Choose Low Volume Part Manufacturing

Low Volume Manufacturing (LVM), a process focused on producing smaller quantities of parts or products, is increasingly gaining traction across various industries. This approach is particularly advantageous for businesses looking to manage resources efficiently while staying adaptive to market changes.

In this blog, we will explore seven key benefits of low volume part manufacturing, highlighting why it is an essential strategy for businesses aiming for cost-effectiveness, flexibility, and innovation in today’s dynamic market environment.

What is Low Volume Part Manufacturing?

Low Volume Part Manufacturing (LVM) refers to the process of producing a smaller quantity of items, typically ranging from tens to a few thousand units, in contrast to traditional mass production methods. This approach is designed to meet specific needs, such as customized products, market testing, or limited edition items, where producing large quantities is unnecessary or impractical.

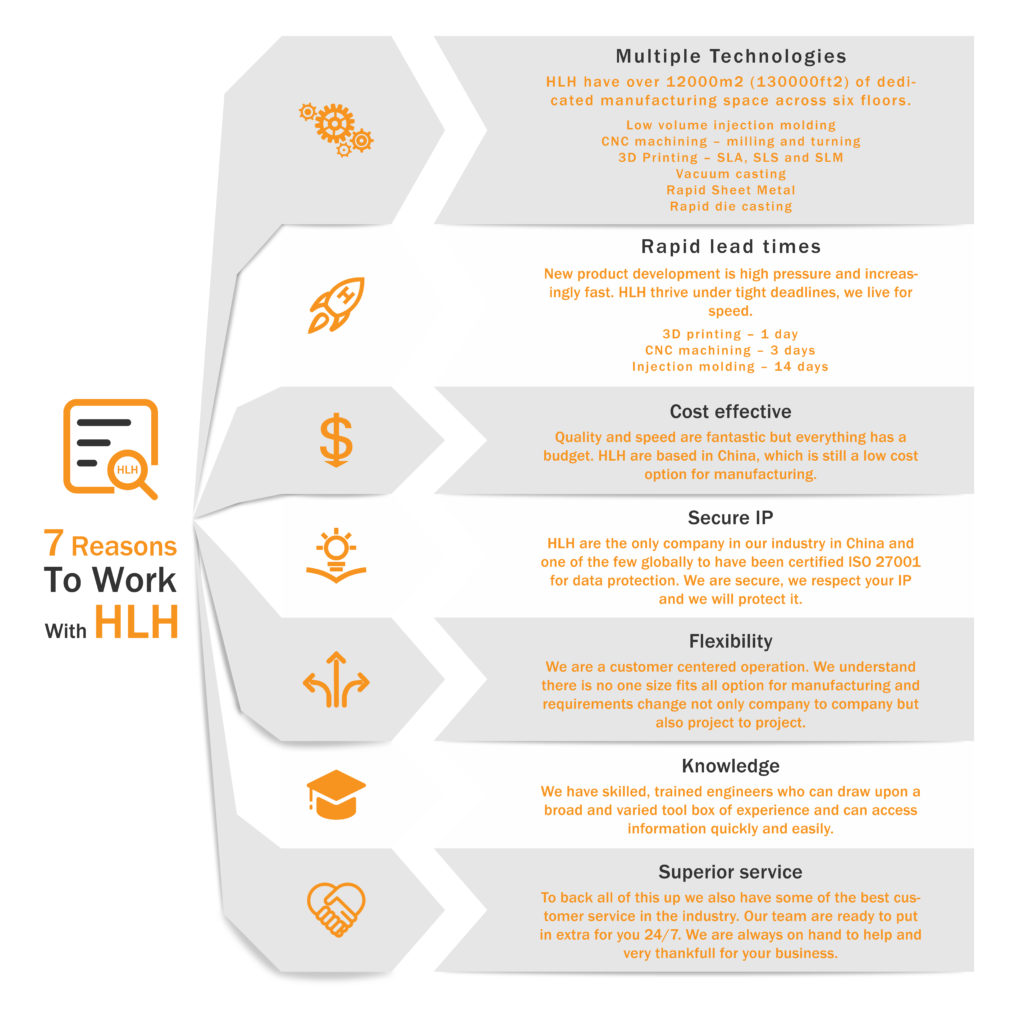

LVM involves using manufacturing techniques that are cost-effective and efficient for small-scale production runs. These may include methods like CNC machining, 3D printing, or injection molding with simplified tooling. The key characteristic of LVM is its scalability and flexibility, allowing manufacturers to produce parts as needed, reduce waste, and adjust production in response to market demands or design changes.

This manufacturing strategy is increasingly popular in industries such as aerospace, medical devices, automotive, and consumer electronics, where the need for precision, customization, and rapid product development is high. It offers a balanced approach between bespoke handcrafting and full-scale mass production, meeting the modern demands of speed, efficiency, and customization.

1. Low Volume Manufacturing is Cost-Effectiveness

One of the primary advantages of low volume manufacturing (LVM) is its cost-effectiveness, particularly evident in the reduction of upfront costs. Traditional mass production often requires significant investment in raw materials, tooling, and machinery. In contrast, LVM allows for the production of smaller quantities, which means lower initial expenditure on these resources. This aspect is especially beneficial for startups and small businesses where budget constraints are a common challenge.

Producing in smaller batches also offers financial flexibility. Businesses are not tied down by large quantities of a single product, enabling them to allocate funds more effectively across different projects or operational areas. This approach minimizes the risks associated with unsold inventory, a critical factor for companies testing new markets or product lines. In summary, LVM presents a financially prudent option for businesses looking to manage their budgets wisely while maintaining the ability to respond quickly to market demands.

2. Low Volume Production Offers Flexibility

Low Volume Manufacturing (LVM) stands out for its inherent flexibility in production volume adjustments. This flexibility allows businesses to scale production up or down based on current market demands and trends without incurring significant costs or delays. For instance, if a product experiences a sudden spike in demand, LVM enables companies to increase production quickly and efficiently. Conversely, if the demand decreases, scaling down is equally feasible, preventing overproduction and excess inventory.

This adaptable approach to manufacturing is particularly advantageous in today’s fast-paced market, where consumer preferences and trends can shift rapidly. Businesses using LVM can respond more swiftly to these changes, allowing them to stay competitive and relevant.

Additionally, this flexibility is crucial for businesses experimenting with new products or entering new markets, as it reduces the risks associated with committing to large production volumes before establishing product viability. In essence, the flexibility offered by LVM is a key factor in enabling businesses to remain agile and responsive in a dynamic market environment.

3. Faster Time-to-Market

With low volume manufacturing, the production cycle is notably shorter. This acceleration is due to streamlined processes, fewer production steps, and less time spent on setting up large-scale production lines. Businesses can go from design to finished product much more rapidly, enabling them to introduce new products into the market at a faster rate.

This rapid market entry serves as a competitive advantage. In industries where trends and consumer demands evolve quickly, the ability to quickly launch new products can be a deciding factor in capturing market share. Companies using low volume manufacturing can adapt and innovate faster, keeping them ahead in competitive markets.

4. High Quality and Customization

Low Volume Manufacturing (LVM) not only accelerates production but also enhances the quality and scope for customization. In LVM, smaller production runs allow for more hands-on and detailed quality control. Each part or product receives greater individual attention, ensuring higher quality standards and fewer defects. This meticulous approach to quality is less feasible in high-volume production, where the focus is often on quantity and speed.

Moreover, LVM opens the door to extensive customization and personalization options. With the flexibility to produce in smaller quantities, manufacturers can easily adapt to specific customer requests or market niche requirements without the need for large-scale changes in the production setup. This capability is particularly valuable in markets where consumer preference leans towards unique, tailor-made products. LVM’s adaptability in design and production makes it an ideal choice for businesses aiming to offer customized solutions and thereby enhance customer satisfaction and loyalty.

low volume injection molding specialist

5. Reduced Risk and Investment

A significant advantage of Low Volume Manufacturing (LVM) is the reduced financial risk and lower investment requirements. In low volume production, companies are not compelled to invest heavily in large quantities of raw materials, extensive machinery, or expansive storage facilities. This reduction in initial investment and fixed costs is particularly beneficial for businesses with limited capital or those cautious about overextending their financial resources.

Furthermore, LVM minimizes the risks associated with inventory management. By producing in smaller quantities, companies avoid the pitfalls of excess inventory, such as obsolescence, storage costs, and potential waste. This lean approach to inventory aligns with just-in-time production philosophies, ensuring resources are utilized more efficiently and effectively. The reduced financial exposure and lower inventory levels make LVM a prudent choice for businesses seeking to maintain financial agility and minimize risk.

6. Ideal for Testing and Prototyping

Low Volume Manufacturing (LVM) plays a crucial role in product testing and prototyping, a stage vital for product development and innovation. LVM’s suitability for producing small quantities makes it an ideal approach for creating prototypes and test units. This capability allows companies to experiment with new ideas and designs without the financial burden of mass production.

The process of iterative design, where a product undergoes multiple revisions based on feedback and testing, is greatly facilitated by LVM. Manufacturers can quickly produce a prototype, test it, gather feedback, and then refine the design. This cycle can be repeated as needed with minimal cost implications, leading to a more polished and market-ready product. This flexibility in making design changes and improvements is less feasible in high-volume production due to the cost and time constraints. LVM, therefore, becomes a key enabler in the innovative process, allowing for rapid prototyping

7. Sustainable and Environmentally Friendly

Low Volume Manufacturing (LVM) is not only a strategic choice for businesses but also a more sustainable and environmentally friendly option. This manufacturing approach significantly reduces waste, as producing smaller quantities directly translates to fewer materials used and less waste generated. This aspect is particularly important in today’s eco-conscious market, where sustainability is a key consideration for both businesses and consumers.

Additionally, LVM contributes to energy efficiency. Smaller-scale production typically requires less energy than mass production processes, leading to a lower carbon footprint. Efficient use of resources in LVM also means less strain on natural resources, aligning with sustainable business practices and contributing to broader environmental conservation efforts.

Conclusion

Throughout this blog, we have explored the multifaceted benefits of Low Volume Manufacturing, from cost-effectiveness and flexibility to faster time-to-market, high quality and customization, reduced risk and investment, suitability for testing and prototyping, and its sustainable nature. LVM emerges as an effective strategy for businesses across various sectors, particularly those seeking to navigate the dynamic market landscape with agility and responsiveness.

By adopting low volume part manufacturing, businesses can not only optimize their operational efficiency and innovation potential but also contribute to environmental sustainability. This approach aligns with the evolving demands of the modern market, making it an essential consideration for companies aiming to remain competitive and forward-thinking.