Start making today - get in touch for free quote and project review

3D Printing Prototyping

Custom 3D Printing has quickly shown itself to be future of manufacturing and is opening up a world of 3D prototyping and low-volume rapid manufacturing possibilities.

We at HLH have been providing online 3D printing prototyping services for over 10 years, including online 3D services. Rapid prototyping via SLA and SLS, paired with our extensive experience – enables us to deliver high precision, high-quality parts & 3D prototypes to customers all over the world.

What’s The Difference between SLA and SLS 3D Printing ?

SLA 3D Printing Online

Our custom SLA Printing Service uses a liquid resin, which is printed in 3D, then cured to solidify – and is one of our most popular online 3D printing services. A precise laser cures the liquid resin in the build chamber, which builds accurate parts one layer at a time. Please see here for more info or contact us for more information about our 3D metal printing service.

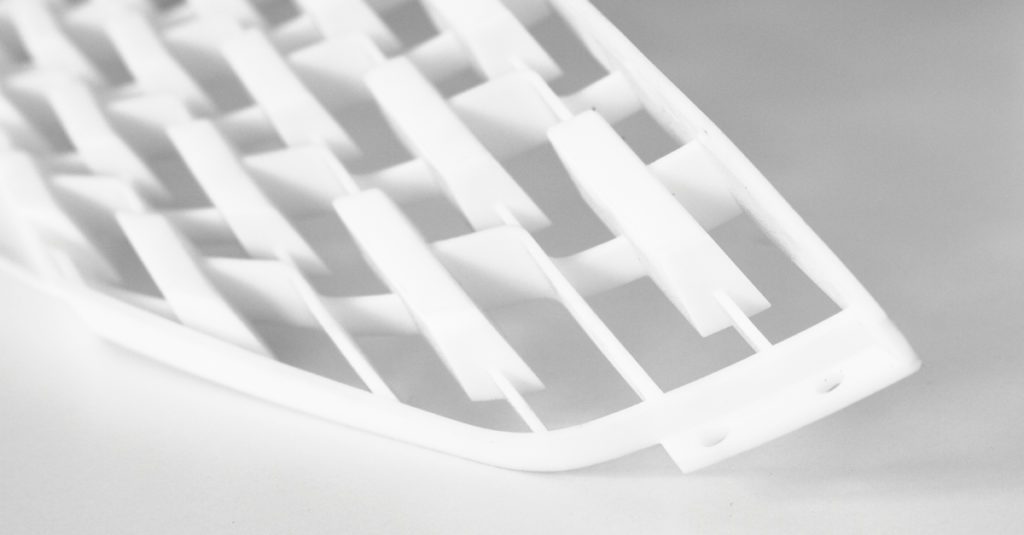

SLS 3D printing

process uses powdered components. which are selectively fused into during the printing process. Here a precision laser fuses powder material together one layer at a time, to build accurate and strong nylon parts. SLS Printing is ideal for functional, more durable, high-stress parts & components. For more info please click here.

Tolerances

SLA: 0.4mm

SLS: 1mm

Please contact our online 3D services team today, for a free project review!

Testimonials

Advantages Of Our 3D Printing Service

- Custom 3D printed parts accurate to CAD

- Online 3D print services delivering fast rapid prototyping

- SLA and SLS delivers good surface finishes

- Strong, rapid prototypes and end-use parts

- Complex geometry solutions

3D Printing Is Used For

3D Printed Functional models

Quick fit, form and function rapid prototypes, aesthetic prototypes, low-volume production parts, master models or patterns, functional prototypes.

Download our prototype materials guide here, and material specification sheets here. Follow us on Facebook or LinkedIn for daily tips, advice, trends, and opinions on rapid manufacturing.

Start Your Free Project Review

3D Printing Prototyping Tips

For 3D printing prototypes, there are many simple design rules to follow which can improve the results of the parts you print. Minimum feature size is one example. Logos and other fine detailed features need to be designed a minimum size to print.

For SLA: 0.4mm wide and high

For SLS: 1mm wide and high

Download our SLS 3D Printing design tips here, and SLA 3D Printing design tips here.

Whether you are looking for concept models (appearance models), rapid prototyping for functional parts, or direct digital manufacturing for series production end-use parts, it is important to look for flexibility when searching for prototyping companies.

At HLH, we are highly aggressive on 3D print pricing, so much so that we can often deliver parts faster and cheaper than local suppliers in your home country, even with shipping costs and distances taken into account. Plus, we can take your part to the next level with our advanced surface finishing options that can turn a good part into a great part that will help you sell.

To learn more talk to our rapid manufacturing team today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...