Start making today - get in touch for free quote and project review

CNC Machining Service

CNC Machining Services

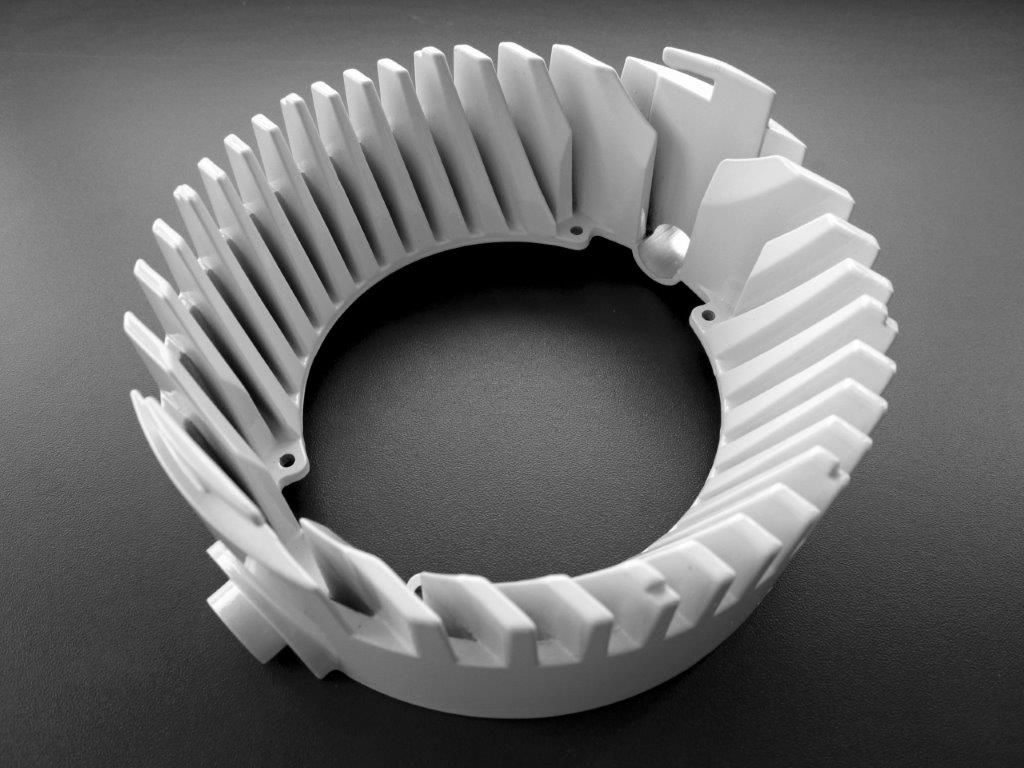

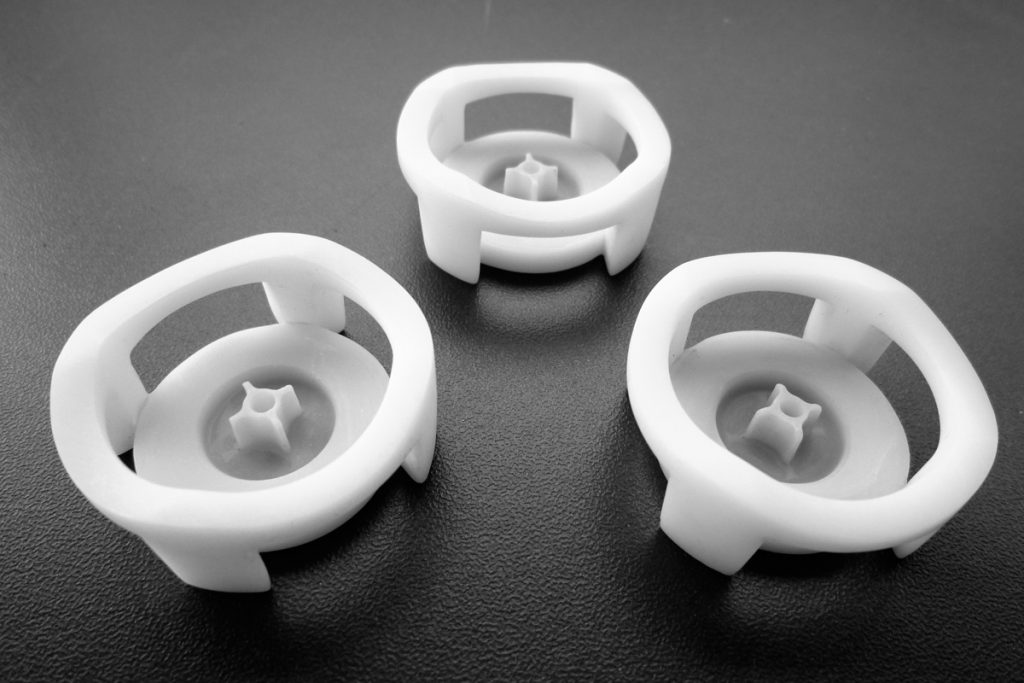

We specialise in Rapid prototyping using CNC machining to provide high-speed, high-precision and robust CNC manufacturing services & products to customers all across the world.

Our cnc machining services start with a solid block or billet of material and cut away precisely, with a series of tools and drill bits, carefully removing material in order to form the desired shape.

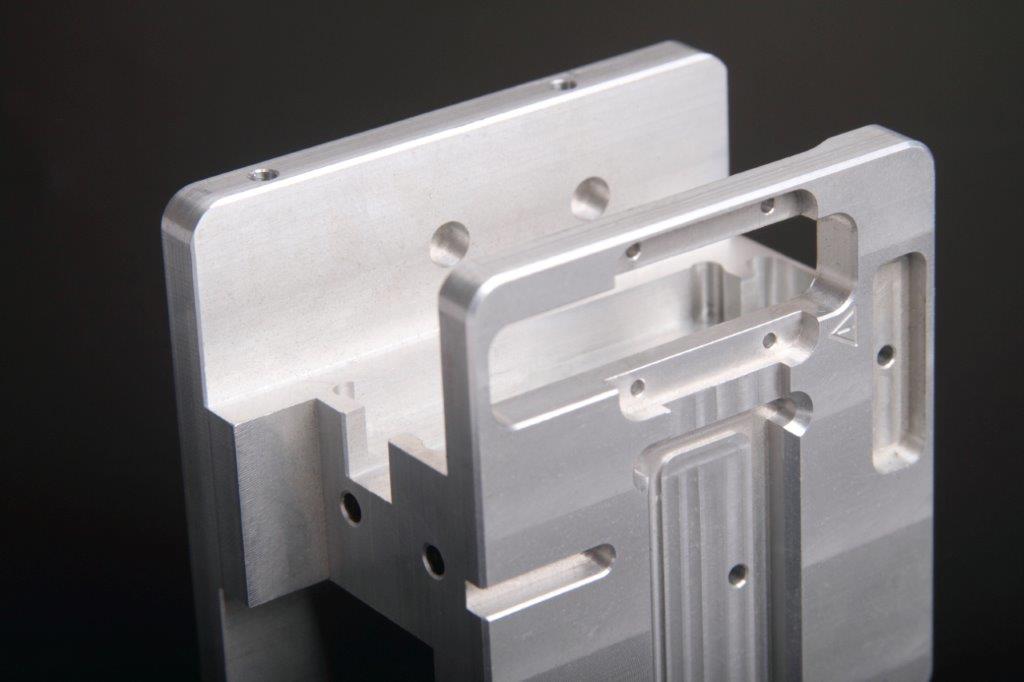

CNC machined parts & products by HLH, work to very fine tolerances, ensuring we provide CNC machined items to your exact specifications. As a result: all of our products conform to ISO 2678-1 International Tolerance legislation.

How CNC Machining Works – At HLH, our CNC machining services deliver parts made from a wide range of plastics and metals. Over 50 high precision CNC mills, lathes, sink and wire EDMs and surface grinding machines – enable us to deliver custom CNC machining for a wide variety of industries & clientele. Read more about our rapid prototyping solutions, or contact us today for free project review.

3, 4 and 5 axis machines are available at HLH. A massive range of materials both metal and plastics are available at HLH. To view the wide range of Materials used in our CNC prototype service, please click here.

Testimonials

Precision CNC Machining Servicing

CNC machining processes and operations include the following:

- CAD model Design

- CAD file to CNC program conversion

- CNC machine or CNC machining fabrication

- Tolerance monitoring for ISO 2678 compliance

What is Custom CNC Machining used for?

- Fast duplicate items for low volume manufacturing

- CNC prototypes requiring high tolerance specifications

- All kinds of production and rapid prototype manufacturing

- Rapid machined items requiring high quality surface finishing

CNC Machined parts are precise and have high tolerance specifications; the process itself is fast and a wide range of materials can be used. Due to these qualities, CNC is a popular choice in the automotive industry.

What is Custom CNC Machining used for?

- Precision CNC

- Machining Parts

- Rapid prototyping

- Metal parts

- Performance plastics

- Low-mid volume production runs

- Rapid Machining

When it comes to China CNC machining or custom CNC machining in general, our approach is: provide highly flexible rapid low volume manufacturing solutions that deliver superior parts, fast.

Follow us on Facebook or LinkedIn for daily tips, advice, trends, and opinions on rapid manufacturing. For fast parts, click below to start.

Start Your Free Project Review

CNC Machining Services Tips

Each rapid prototyping service has its own unique design rules that, if followed, will help you design highly successful rapid prototypes. For precision CNC machining there are many simple design rules that will generally improve your CNC prototype design and will not adversely affect the overall look or functionality of your part made via low volume manufacturing.

Hole depth is one design tip example. Try to keep the hole depth to diameter ratio at 10:1 or less to make for easy CNC machining. Anything deeper than this could require a deep hole drilling process step. To get HLH Prototypes top prototype manufacturing design tips for precision machining click here.

For further rapid prototyping design tips including: prototype injection molding design tips, vacuum casting design tips (urethane molding), 3D printing prototype design tips (including SLA prototype and SLS prototype) check out our rapid prototype manufacturing design tip page.

Our core focus is rapid prototypes that start with an MOQ of 1 and low volume manufacturing solutions up to 100,000 parts. We don’t box you into rapid manufacturing solutions that are good for us. Instead we work with you to create bespoke solutions that work for your project needs. At HLH Prototypes, we make things for you…FAST!

To start your free project review talk to our rapid projects teams today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...