Start making today - get in touch for free quote and project review

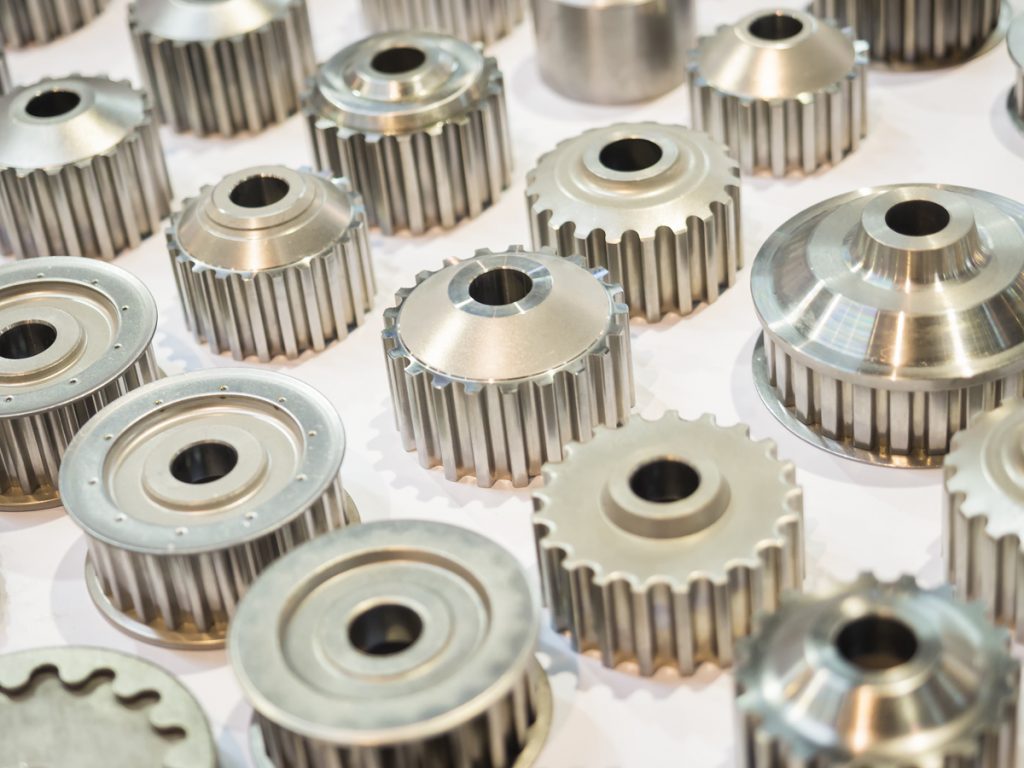

Zinc, Magnesium & Aluminium Die Casting Manufacturer

Pressure die casting is great for manufacturing higher volumes of metal parts in aluminium, zinc or magnesium. HLH manufactures high quality die cast tools & precision die casting, post process machining and high quality finishing options.

How It Works – Similar to injection molding but for metals, a mold tool is first manufactured by HLH’s highly skilled toolmakers and engineers. This is then installed on a die casting press and molten metal is injected under pressure into the tool cavity. The parts can then be finished in a range of ways including powder coating and anodizing.

Testimonials

Advantages of Die Casting Manufacturing

- Lower cost per part

- Accurate and repeatable

- Good surface finish and range of treatments

- Good for larger and more complex parts

Where is Die Casting Manufacturing used?

Die casting is used for low to mid volume metal part production, production metal parts, complex metal parts

Start Your Free Project Review

Die Casting Tips

When it comes to any design, to achieve ultimate project success it is good to check your design against your chosen manufacturing process to see if any changes are needed. For die casting there are many things to consider to ensure you get a better quality of part.

Applying proper draft is crucial in die casting to ensure you get a consistent part without warpage or surface defects. The exact amount of draft you need to add depends on the part and tool design but get in touch early in the process and we can advise.

To learn more talk to our rapid manufacturing team today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...