Start making today - get in touch for free quote and project review

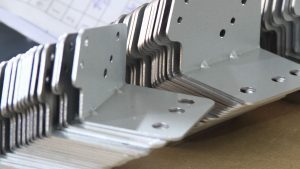

Sheet Metal Rapid Prototyping

Sheet metal parts are found almost everywhere and HLH can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. HLH use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Testimonials

Advantages of Sheet Metal manufacturing

- Quick and inexpensive

- Hard wearing

- Flexible solutions

- Range of materials

What is sheet metal production used for?

Prototypes and low volume production, medical and communications products, housings and enclosures

Start Your Free Project Review

Sheet Metal Tips

Sheet metal parts are some of the most versatile and inexpensive parts you can use to create your product. There are a number of different processes utilised to manufacture sheet metal parts and assemblies each with their own considerations.

Bending radii are one consideration when looking to keep costs down. As far as possible if you can maintain all the same radii on the bends there will be less setups, the process will be quicker and cheaper.

To learn more talk to our rapid manufacturing team today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...