What rapid manufacturing process is best?

It’s a trick question. There is no best rapid manufacturing process but there are processes that will better align with the needs of your project and/or budget. At HLH we don’t push one manufacturing process over another. Instead we take the time to review your project and offer you guidance on different rapid prototyping and low-volume manufacturing processes that will work for you.

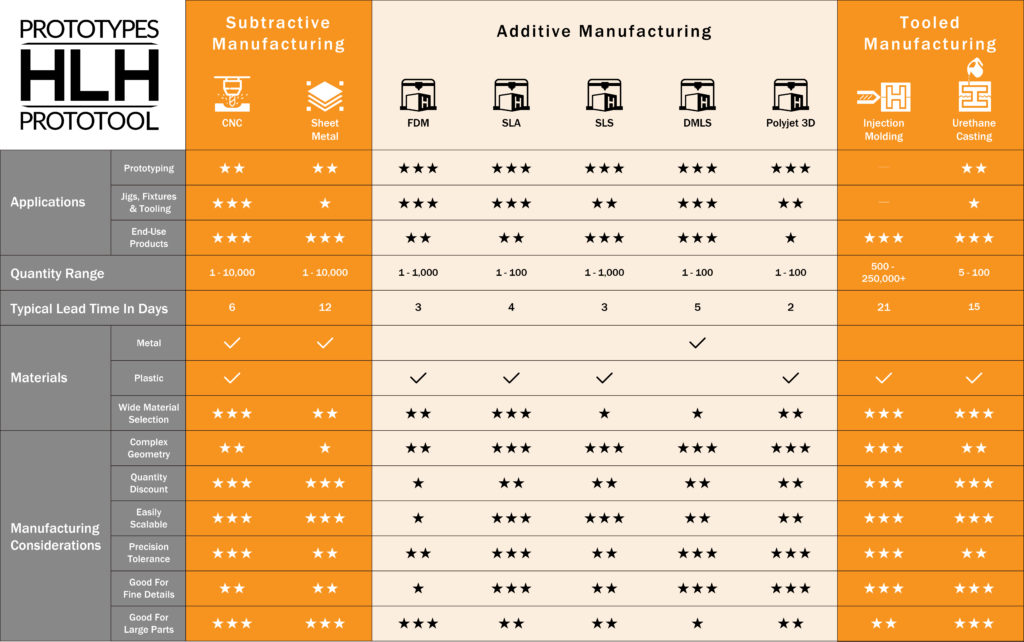

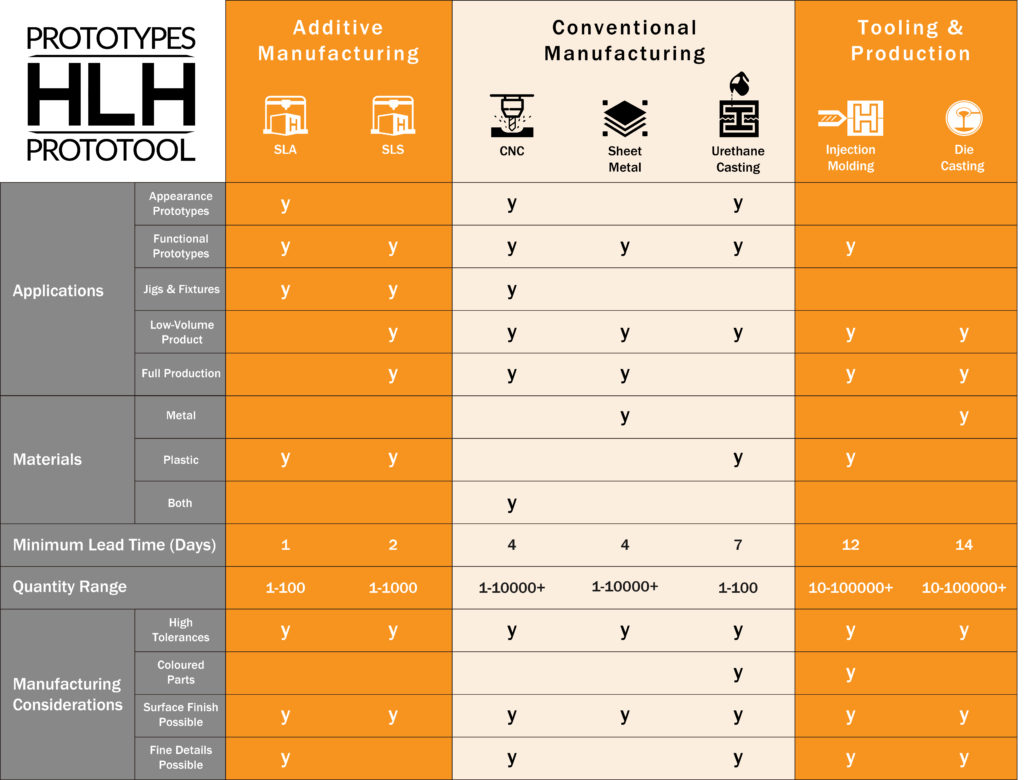

Below are insights into how different rapid prototyping and manufacturing processes are used, the typical timing of each process, the quantity range that each process can handle, and many other considerations that you will want to weigh up before choosing a rapid parts process that works for you. You can also download the tables below right here.

What rapid manufacturing process options do we offer at HLH? CNC machining, 3D printing, vacuum casting (urethane casting), rapid injection molding, die casting, carbon fiber, and sheet metal are the core manufacturing services we offer.

Why do people choose HLH? Experience and advanced English communication skills are two big reasons why our customer’s keep coming back to HLH. We deliver on time, we fix problems quickly, and we help to identify any potential design issues before they become a problem. Our team will help guide you to the right rapid manufacturing process.

At HLH, we make things for you. Talk to our rapid project team today for further insight into making the right choice for your rapid prototyping or low-volume manufacturing project. FreeQuote@HLHPrototypes.com

Follow us on Facebook or LinkedIn for daily tips, advice, trends, and opinions on rapid manufacturing.