Rapid Product Development

HLH collaborates with industrial design and engineering consultancies, crucial to our business and renowned for their innovation and creativity.

We specialize in Rapid Product Development, working globally with product designers to prototype and manufacture state-of-the-art products.

Our extensive, customer-focused services support rapid iteration and swift delivery of customized solutions, catering to the fast-paced demands of product development. We understand the importance of precision and efficiency in your projects.

At HLH, we’re committed to ensuring your Rapid Product Development needs are not only met but exceeded, aligning with your goal of perfection in every endeavor.

What is Rapid Product Development

Rapid Product Development (RPD) is a methodology focused on speeding up the design and development process of new products.

It integrates various techniques such as prototyping, iterative design, and advanced manufacturing processes, including 3D printing and CNC machining.

The goal of RPD is to quickly bring a product from concept to market, allowing for frequent revisions and adaptations based on feedback or testing.

This approach is highly beneficial in industries where innovation cycles are short and time-to-market is critical. RPD enables companies to stay competitive by rapidly responding to changing market demands and technological advancements.

Testimonials

Rapid Product Development Common Applications

Prototypes and Models: Creating high-fidelity prototypes and models that accurately represent the final product.

Fit, Form, and Function Testing: Ensuring that products meet design specifications in terms of size, shape, and functionality.

Rapid Iterations: Quickly modifying designs based on feedback or testing results to optimize product performance.

Low Volume Production: Producing small batches of products for pilot testing or initial market introduction.

Market Testing: Utilizing rapid development to create products for market testing, gathering consumer feedback and data for further development.

Rapid Product Prototyping Capabilities

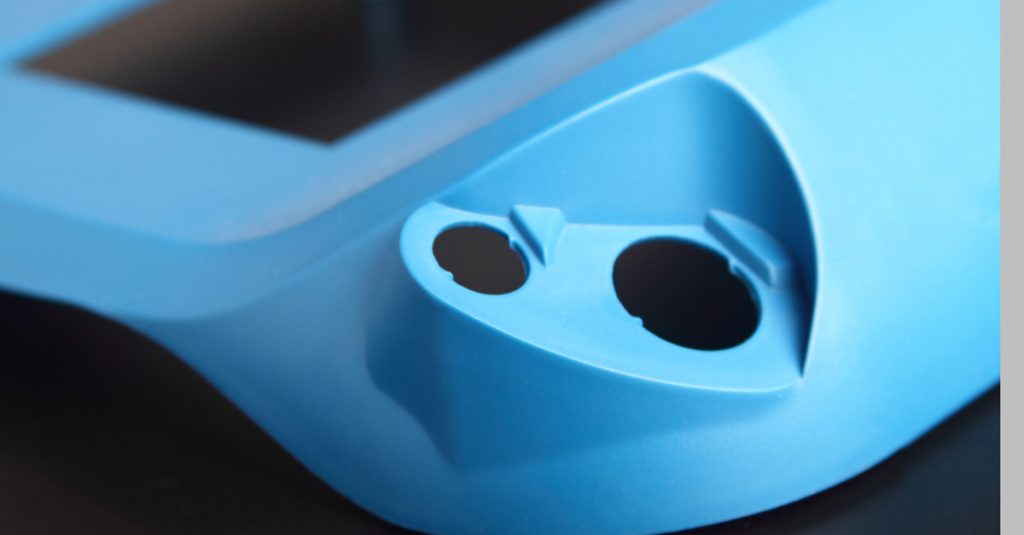

At HLH, we produce prototype and low-volume new products via CNC machining, 3D printing, rapid injection molding, die casting, sheet metal, vacuum casting (urethane casting), and more

Rapid Product Development Tips

Rapid Product Development Tips

Product design and development companies need prototypes and models and demand high quality:

3D Printing: quick iterations, design validation

CNC machining: great for appearance prototypes

Rapid Injection molding: low volume production and bridge tooling

To start your free project review email HLH today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With HLH “We started our cooperation with HLH because we needed a partner which...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by which parts are manufactured by injecting material under pressure into a mold...