The Advantages of Using Rapid Prototype CNC Machining for High-Quality, Low-Volume Production

Creating a rapid prototype with CNC machining allows you to realize your new product design quickly and cost-effectively. This approach also seamlessly transitions into low-volume production, which we can assist you with. At HLH Prototypes, we customize our CNC machining service to meet your manufacturing needs. Whether you require prototypes or low-volume end-use parts, our team will deliver precise, high-quality, and robust parts quickly and at a reasonable cost.

In this blog, we will explain how our CNC machining service can benefit your low-volume manufacturing.

A speedy manufacturing process

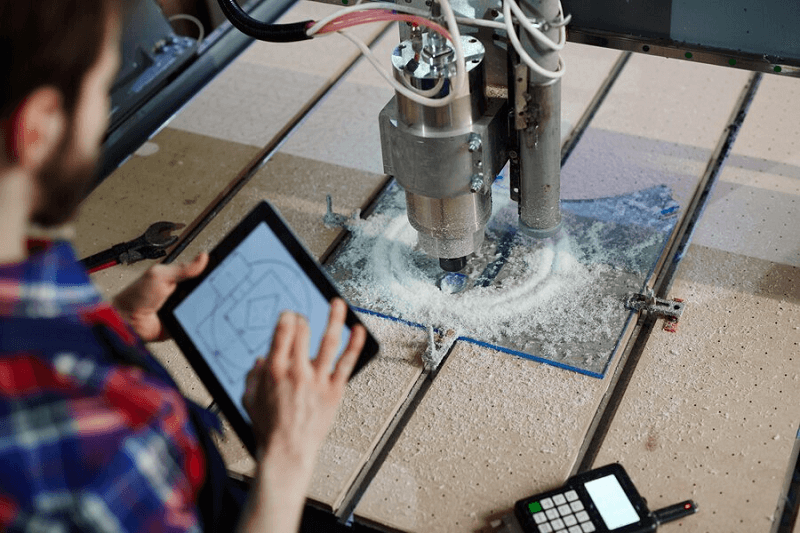

Rapid prototyping with CNC machining is a strategic way to move from product design to end-use production quickly and cost-effectively. We can turn your CAD file into a digital cutting guide for the CNC machine in a matter of hours. Cutting can be completed in minutes without compromising accuracy using our 3, 4, and 5-axis machines.

Precision

At HLH Prototypes, we offer a wide range of plastics and metals that we cut with a series of carefully selected drill bits and tools. We have more than 50 high-precision CNC mills, surface grinding machines, sink and wire EDMs, and lathes that allow us to customize the process to meet your specific requirements. All of these ensure precise results that conform to the finest tolerances per ISO 2678-1 standards.

Flexibility

At HLH Prototypes, we customize rapid prototyping solutions and CNC machining to meet your required volume of parts. Whether you need one of up to 100,000 custom parts, we will deliver. This can be beneficial when introducing a new product, but it is unclear how it will do in the market. Likewise, it allows you to meet industrial products with unpredictable demand cycles, as you can scale the volume of parts without worrying about overstocking.

Quality results

CNC machines can produce fully functional, high-strength parts that are ready for use. This is a crucial advantage if you’re designing and manufacturing a part that must meet stricter engineering requirements. This quality also applies to the part’s aesthetics and surface finish, especially when we use the right cutting tools at appropriate speeds.

Contact us today!

Whether you need end-use parts or a rapid prototype with CNC machining, we can help you realize your project as soon as possible. Contact us now so we can review your project. Call +86 755 8256 9129 or fill out our form here.