A Comprehensive Guide to CNC Machining Processes

Many companies rely on CNC machining in China for end-use production, but it’s also become a cost-effective choice for designers and engineers developing new products. CNC machining offers a high level of precision and fast turnaround, making it ideal for producing plastic and metal parts across a wide range of industries. It’s a proven method for manufacturing many of the products we use every day — from consumer goods to industrial components,

But how does it work and what’s involved in the CNC machining process? We’ll explain the answers in this blog.

A quick look at the process

Every CNC project starts with a CAD (computer-aided design) file of your part. From there, we use CAM (computer-aided manufacturing) software to convert the 3D model into G-code—the language that controls the CNC machine. This code includes everything: tool paths, material specs, tool changes, and even commands to activate auxiliary components.

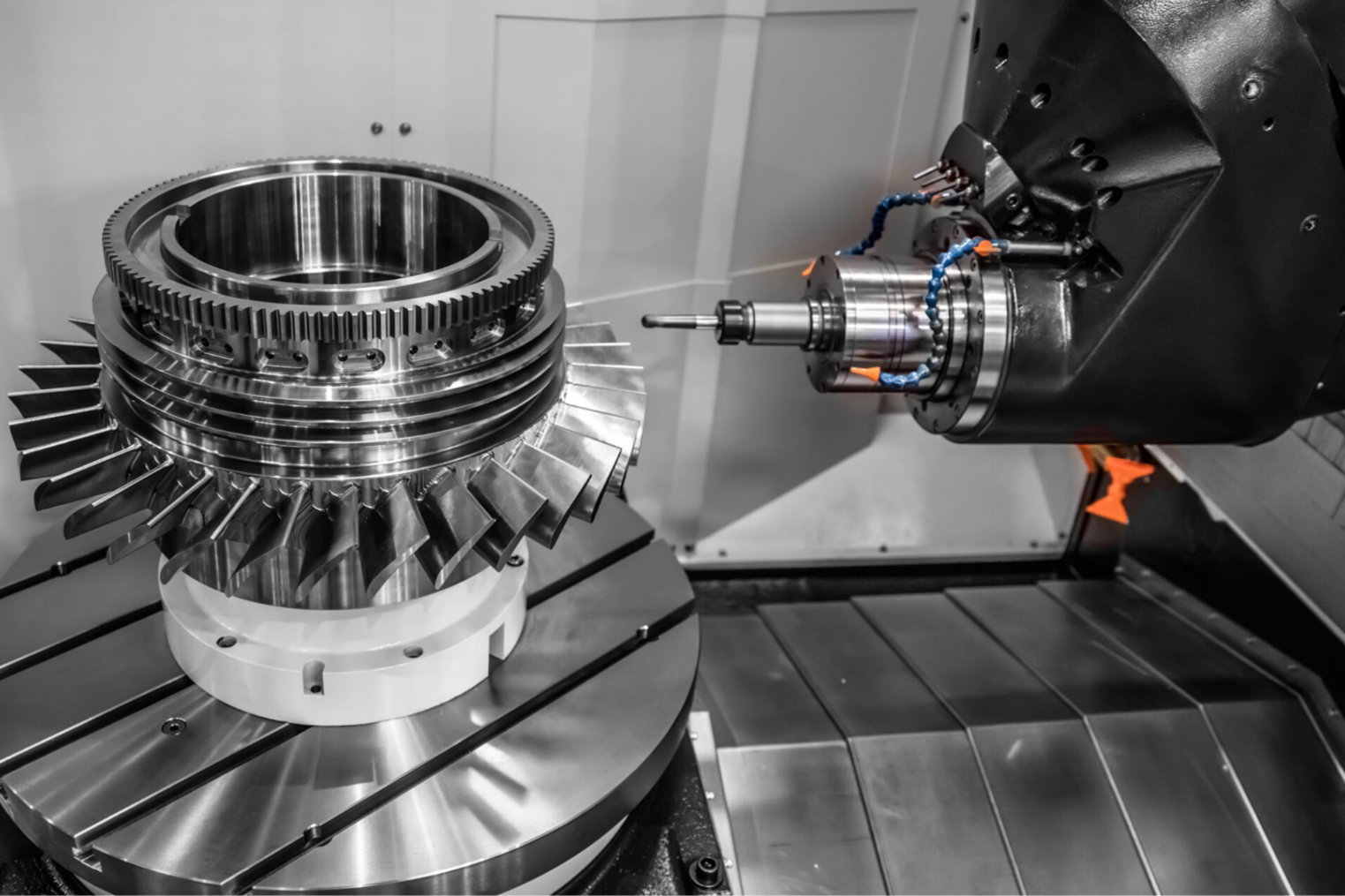

Once the program is ready, the CNC machine cuts your part from a solid block (or billet) of material. The process is fully automated and repeatable, which helps maintain accuracy across every piece—whether you’re making one or one thousand.

CNC machining in China works with a broad range of materials, including aluminum, steel, ABS, and nylon. We can guide you in selecting the right material for your part to match both your performance needs and your budget.

Our Process

At HLH Prototypes Co. Ltd, we start every project with careful material selection. Once we understand what you need, we choose and configure the right tools—such as drill bits and cutting heads—to shape the part accurately. These tools remove material step by step until your part reaches the exact dimensions and form. To ensure top-level precision, we follow ISO 2768-1 tolerance standards throughout the process.

The tools we use for CNC machining in China

We equip our facility with a full range of advanced machinery to support projects across different industries. Our capabilities include CNC mills, sink and wire EDMs, lathes, and precision surface grinders. For more complex geometries or faster turnaround, we rely on 3-, 4-, and 5-axis machines. These systems are not only easier to program but also reduce manual intervention, allowing us to deliver high-quality results efficiently.

Discover the benefits of CNC machining

Call +86 755 8256 9129 for any questions about our services. We can review your project at no cost and offer design tips to make your part suitable for CNC machining in China.