Low Volume Injection Molding Is Changing How Products Get Made

Injection molding has long been linked with mass production, but that’s changing. Manufacturers in China are using low volume injection molding to turn out smaller batches quickly without the high upfront tooling costs you’d expect.

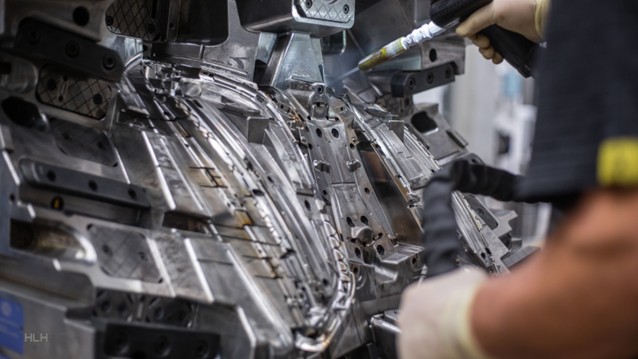

Low-volume, high-quality parts

Through low volume injection molding, manufacturers can make small quantities of plastic parts with precision and quality, all while keeping costs down. It reduces tooling and setup expenses, making it a smart solution for prototyping and custom orders. Today, it’s widely used in industries that require fewer parts without sacrificing performance or accuracy.

A flexible approach to production

Whether you need parts for pilot runs or functional prototypes, small-batch injection molding will ensure that they closely match those made using mass production. So, you can still test and verify designs confidently before committing to larger orders.

Reliable materials

Low volume injection molding supports a wide range of reliable materials:

- Thermoplastics are the most common choice thanks to their easy moldability and versatile properties

- Thermosets are perfect for parts that require reliable heat resistance

- Elastomers are ideal for parts that need flexibility.

Thermoplastics like nylon and ABS are popular for their flexibility and consistent molding results. They deliver durable, high-performance parts required for both prototypes and short-run production without compromising quality.

Speeding up production timelines

Compared to traditional manufacturing, injection molding can accelerate the production cycle and decrease your time to market. Most manufacturers use aluminum molds because they’re easier to work with and quicker to produce than steel molds. This significantly shortens mold production time and speeds up part delivery.

In many cases, production can start in as little as one day, helping companies bring products to market faster. This approach is used across industries from medical equipment and automotive to aerospace and jewelry—whether for end-use parts or prototypes.

Get started with injection molding

HLH Prototypes offers low volume injection molding that delivers high-quality, production-grade parts—up to 100,000 units—using trusted production resins. Their team is ready to help you meet your project goals.

To learn more, contact HLH Prototypes at +86 755 8256 9129 or request a free project review through their website.