The Future of Manufacturing: Industrial Applications of 3D Printing

The Future of Manufacturing: Industrial Applications of 3D Printing

Prototyping is a necessary evil when designing any new part or product. It’s a crucial stage in product manufacturing that lets you verify the look and function of your design. However, it doesn’t have to be time-consuming when you go for 3D prototyping. By using 3D printing or additive manufacturing, prototyping can be cost-effective, quicker, and more productive for any industry. This guide will discuss the industrial applications of prototyping using 3D printing.

Aerospace and defense: The sky’s the limit with 3D printing

The Aerospace and Defense (A&D) sector has been at the forefront of embracing the boundless potentials of 3D printing technology. As an early adopter of 3D prototyping, the A&D industry has harnessed the power of 3D printing to revolutionize the design and manufacturing processes inherent within its realm. The technology is not merely a tool; it’s a conduit that facilitates the seamless transition from conceptual design to tangible, high-functioning prototypes and end-use parts.

The aerospace industry, in particular, has soared to new heights thanks to 3D printing applications. The necessity for lightweight, durable components is paramount in aerospace design, and 3D printing fits this bill impeccably. Metal 3D printing, a subset of additive manufacturing, plays a crucial role in crafting lightweight yet robust components that significantly contribute to fuel efficiency and overall aircraft performance. Whether it’s intricate air ducts, structural metal components, or meticulously designed wall panels, 3D printing enables the swift and cost-effective production of these essential parts with a degree of precision that was previously unattainable.

One of the stellar aerospace applications of 3D printing lies in its ability to drastically reduce the lead time traditionally required in the manufacturing process. In a domain where every minute detail can impact the broader safety and efficiency matrix, the rapid prototyping afforded by 3D printing is nothing short of a game-changer. It expedites the design-to-production timeline, ensuring that innovative aerospace solutions reach the testing and deployment phases faster than ever before.

3D printing helps in the creation of highly complex, geometrically precise components which are often challenging, if not impossible, to produce through traditional manufacturing methods. This is particularly beneficial in the defense sector, where tailored solutions and rapid adaptability are the linchpins of operational success.

When it comes to spare parts, the ease and speed at which they can be produced and replaced on-demand are unparalleled, thanks to 3D printing. This is especially crucial in mission-critical scenarios often encountered in aerospace and defense settings, where timely access to spare parts can significantly impact mission outcomes.

Additionally, the broad spectrum of 3D printing materials available provides a vast playground for engineers and designers to experiment, iterate, and eventually perfect the components tailored to specific aerospace and defense applications.

Steering the automotive sector with 3D printer technology

The introduction of 3D printer technology in the automotive sector heralds a new era of innovation, significantly elevating the capabilities within prototyping, tooling, and end-use applications. The agility and precision offered by 3D printing are instrumental in accelerating product development cycles, providing automobile manufacturers with a powerful tool to swiftly transition from conceptual designs to tangible prototypes and eventually, market-ready products.

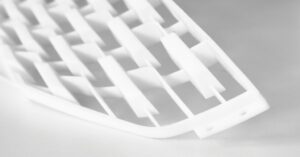

One of the most compelling advantages of 3D printing in automotive is the unprecedented design flexibility. This technology enables the creation of complex geometries like internal channels, fine meshes, and thin walls, which were previously challenging or expensive to produce. It opens up a realm of possibilities for one-of-a-kind designs, catering to the modern consumer’s evolving expectations for customized and unique vehicle features.

One of the most compelling advantages of 3D printing in automotive is the unprecedented design flexibility. This technology enables the creation of complex geometries like internal channels, fine meshes, and thin walls, which were previously challenging or expensive to produce. It opens up a realm of possibilities for one-of-a-kind designs, catering to the modern consumer’s evolving expectations for customized and unique vehicle features.

Furthermore, the rapid prototyping capability of 3D printing is a game-changer in car design and manufacturing. It not only shortens the product development timeline but also significantly reduces the costs associated with traditional prototyping and tooling.

Also, the ability to use 3D printers to produce custom tools and fixtures on-demand is another aspect where additive manufacturing is driving efficiency. This on-demand production capability is particularly beneficial in reducing inventory overheads and ensuring that the production process remains agile and responsive to market demands.

Moreover, the continual advancements in 3D printing processes and materials are expanding the horizons for automotive applications, making it a cornerstone technology destined to shape the future of automotive manufacturing.

Advancements in additive manufacturing

Following the notable impact in the auto sector, the broader landscape of additive manufacturing continues to showcase remarkable advancements. This growing technology, often referred to as additive manufacturing, encompasses a variety of 3D printing technologies and methods. Each comes with unique capabilities and applications, pushing beyond the traditional boundaries of manufacturing.

One significant aspect of additive manufacturing is the wide array of 3D printing materials now available. The range spans from strong metals and durable plastics to flexible filaments and even composite materials, broadening the scope of applications immensely. These materials cater to a multitude of functional requirements and enable a level of design and customization that was previously challenging with traditional manufacturing methods.

Furthermore, the diversification in types of 3D printing, such as Stereolithography (SLA), Fused Deposition Modeling (FDM), and Selective Laser Sintering (SLS), among others, allows for a wide range of applications. Each of these 3D printing methods has its own set of advantages, whether in terms of precision, speed, or the ability to handle different materials. This variety ensures that additive manufacturing can be tailored to meet the specific demands of different industries, paving the way for more innovative and cost-effective solutions. Through these advancements, additive manufacturing is setting a new standard in how we conceive and produce products across industries.

Prototype development through 3D design

The pathway to actualizing a new product traditionally involved a lengthy and often expensive process from conceptualization to prototype development. However, with the introduction of 3D design in additive manufacturing, this pathway has been drastically shortened and simplified. Now, developing prototypes is a much quicker and more cost-effective process, owing significantly to the capabilities of 3D design and printing.

At the heart of this advancement is the ability to create accurate 3D models using modern design software. These 3D models serve as the blueprint for rapid prototyping, enabling designers and engineers to visualize and test their ideas in real-world scenarios before full-scale production. The process of transferring a 3D design to a physical prototype has become simpler and more accurate with the advent of 3D printing.

The term rapid prototyping is nearly synonymous with 3D printing prototyping nowadays, showcasing the significant impact of this technology in prototype development. The 3D printing process allows for the creation of prototypes in a fraction of the time and at a fraction of the cost compared to traditional methods. This speed in development is not only cost-effective but also encourages a culture of innovation and iteration, as designs can be tested and tweaked repeatedly with minimal resource expenditure.

The term rapid prototyping is nearly synonymous with 3D printing prototyping nowadays, showcasing the significant impact of this technology in prototype development. The 3D printing process allows for the creation of prototypes in a fraction of the time and at a fraction of the cost compared to traditional methods. This speed in development is not only cost-effective but also encourages a culture of innovation and iteration, as designs can be tested and tweaked repeatedly with minimal resource expenditure.

Additionally, the examples of 3D printing in creating prototypes are abundant and span across industries. From auto components to consumer goods and medical grade devices, the application of 3D printing for rapid prototyping is pervasive. This process is fostering a culture of innovation, where ideas can be brought to life and tested in real-world scenarios much quicker than before.

Moreover, with a process similar to actual production, 3D printing provides a realistic representation of the final product, which is crucial for garnering stakeholder approval and understanding consumer response before mass production. This way, 3D printing in prototype development not only accelerates the product development cycle but also significantly de-risks the process, leading to better products and faster innovation.

Dental and medical innovations: Implant and medical devices production

The integration of 3D printing in the medical domain has catalyzed a new era of personalized healthcare and sophisticated medical devices production. Utilizing 3D prototyping, dental and medical equipment manufacturers now design and create customized prosthetics, and have made strides in the exciting realm of bioprinting. This innovation plays a pivotal role in delivering personalized healthcare solutions and creating enhanced medical tools at a more accessible price point.

A significant benefit of 3D printing lies in its application for custom dental products such as bite splints, crowns, and bridges, ensuring a precise fit tailored to the patient’s mouth. Employing 3D printers for these purposes not only ensures accuracy but significantly reduces the time traditionally required for lab-based productions.

The potential to produce 3D printed tissues is unlocking new possibilities in treatment methods and research, especially in the field of regenerative medicine. This fascinating application of 3D printing technology is gradually blurring the lines between conventional medical practices and futuristic healthcare solutions.

The potential to produce 3D printed tissues is unlocking new possibilities in treatment methods and research, especially in the field of regenerative medicine. This fascinating application of 3D printing technology is gradually blurring the lines between conventional medical practices and futuristic healthcare solutions.

Medical devices production has also seen a considerable uplift with the adoption of 3D printing services. This is especially apparent in the rapid prototyping of medical tools, where 3D printing applications expedite the design-to-production timeline, facilitating quicker iterations and refinements.

The realm of dental and medical innovations is now widened by incorporating 3D printing. This technology is not only streamlining the production process but also contributing towards more personalized and effective healthcare solutions. Through the use of 3D technology, the dental and medical sectors are experiencing a significant transformation, indicating a promising trajectory for patient-centered healthcare solutions.

Consumer goods: Bringing imagination to the shelves with 3D printing

The relentless competition in consumer-oriented industries necessitates a continual flow of innovative and appealing products to the market, swiftly and cost-effectively. 3D prototyping has become a vital tool in this endeavor, aiding in the design of consumer electronics, sportswear, toys, and many other smart devices. 3D printing allows for a substantial enhancement in product development, considerably accelerating the time-to-market.

One notable benefit is that 3D printing also paves the way for digital manufacturing, where the journey from design to production becomes a streamlined, seamless process. This shift is not just a technical upgrade but a fundamental change in how consumer goods are conceived, designed, and manufactured. With digital manufacturing, the iterations required to perfect a product are faster and less costly, making the innovation cycle more agile and responsive to market feedback.

The range of applications for 3D printing is broad and continually expanding. From creating intricate designs for jewelry to prototyping ergonomic household gadgets, this technology is proving to be an indispensable asset. Brands can experiment with design and function like never before, thanks to the flexibility and precision that 3D printing offers.

Consumer-oriented brands benefit from 3D printing, not just in terms of reduced production time and costs, but also in the vast potential for customization. Modern consumers appreciate products tailored to individual preferences, and the ability of 3D printing to accommodate such customization is a significant advantage.

Additionally, the availability of 3D printing in manufacturing services extends the technology’s reach, making it accessible to brands irrespective of their size or operational scale. This democratization of manufacturing technology is likely to fuel further innovation in consumer goods, as small and large enterprises alike leverage 3D printing to deliver exciting new products to the market.

Industrial 3D: A new era of manufacturing

The influx of 3D printing technology has ushered in a new epoch in the manufacturing sector, prominently seen through the myriad industrial applications of 3D printing. This transition from traditional manufacturing to a more tech-driven approach signifies a substantial shift in how products are conceived, developed, and produced. Unlike the conventional manufacturing process which often involves subtracting materials to achieve the desired shape, 3D printing, or industrial 3D as it’s often called, builds products layer by layer, which not only minimizes waste but also optimizes the production process.

The technology is used to create complex geometries and designs which were previously unthinkable or too expensive to manufacture. Additionally, the technology is being used to expedite the prototyping process, allowing for faster iterations and quicker market entry. The 3D printing capabilities extend beyond mere manufacturing and have started to redefine the boundaries of design and production in the industrial domain.

The future of 3D printing in manufacturing

The horizon looks promising for 3D printing as its applications continue to expand. The future of 3D printing seems intertwined with the evolution of manufacturing. Companies are increasingly turning to 3D printing to enhance their operational efficiencies and product quality. Utilizing 3D printing has shown to reduce lead times, cut costs, and facilitate on-demand production, marking a departure from traditional manufacturing constraints.

Moreover, the advantages of 3D printing are being realized across a wide spectrum of industries. From students who can make 3D models to understand complex concepts better, to large manufacturing setups integrating industrial robots with 3D printing capabilities to optimize production lines – the symbiosis between 3D technology and manufacturing is growing stronger.

Final thoughts

The transformative journey of manufacturing, thanks to 3D printing, marks a pivotal point in how products are designed, tested, and produced. The materials and methods used in 3D printing are continually evolving, expanding the scope and scale of its applications. From items used to 3D print intricate components to large-scale assemblies fabricated by 3D printing, the realm of possibilities keeps widening.

Additionally, the advent of 3D scanning has further bolstered the 3D printing ecosystem, enabling precise replication and analysis of real-world objects. This augmentation is not merely a technical transition but a strategic one, aligning with the modern-day imperatives of customization, speed, and efficiency. Hence, 3D printing also paves the way for a more innovative, sustainable, and efficient future in manufacturing.