A Guide To Rapid Prototyping

What is rapid prototyping?

Rapid prototyping is a game-changing approach in the world of product development and a must-have skill for any product manager aiming to stay ahead of the competition.

At its core, rapid prototyping is the practice of swiftly creating a prototype to validate design decisions early in the design process. This process often involves creating high-fidelity prototypes that closely resemble the finished product in both functionality and design.

One of the primary advantages of rapid prototyping is its ability to help avoid costly mistakes early on. By quickly creating the model, teams can make changes, perfect ideas, and iterate on designs before committing significant time and resources. This results in fewer iterations needed, expediting the journey from an idea to the complete product.

Another benefit lies in its speed. The fast-paced nature of rapid prototyping can drastically reduce time-to-market, allowing teams to swiftly adapt and validate ideas without fully investing in them. This agility in the design process facilitates prompt feedback from users and stakeholders alike. Such feedback is invaluable as it helps to inform and refine design decisions, ensuring a superior user experience in the complete product.

The rise of 3D printing in rapid prototyping

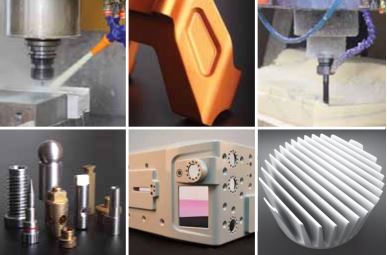

As rapid prototyping has evolved, so too have the tools and techniques that empower it. One of the most transformative advancements in this realm has been the advent of 3D printing. Using tools like a 3D printer, teams can now literally “print” their ideas into tangible, three-dimensional objects in a matter of hours. This technology, often referred to as additive manufacturing, has revolutionized how prototyping is used to create high-fidelity models.

The power of 3D printing in rapid prototyping lies in its ability to bring concepts to life quickly and with intricate detail. Before the rise of 3D printers, creating a physical prototype could be a labor-intensive and time-consuming process. Now, with the press of a button, designs are transformed into physical entities, allowing teams to start prototyping with ease. This immediacy not only expedites the design process but also enhances the quality and precision of prototypes, ensuring they closely mirror the envisioned final product.

In-house rapid Prototyping VS external rapid prototyping services

As rapid prototyping helps streamline the product development process, businesses often face a pivotal decision: to invest in in-house rapid prototyping tools or to leverage external rapid prototyping services. Both approaches come with their own sets of advantages.

Having in-house prototyping capabilities, such as owning a 3D printer and other rapid prototyping tools, provides teams with direct control over the prototyping system. This can lead to faster iterations, as there’s no need to wait on external vendors. Teams can also tweak and adjust designs on-the-fly, ensuring that the prototyping methods employed align perfectly with the project’s needs.

On the other hand, external prototyping services often come with a wealth of experience and expertise. These services typically have a broader array of tools and technologies at their disposal, allowing for a wider range of prototyping methods to be used. For businesses that may not prototype frequently or those that need specialized prototypes, using prototyping services can be cost-effective and efficient.

Ultimately, the choice between in-house and external services hinges on the specific needs of the project and the resources available. Whether a business uses rapid prototyping to create designs in-house or through external services, the primary goal remains the same: to bring ideas to life swiftly and effectively.

Benefits and advantages of rapid prototyping

Rapid prototyping is a highly efficient method that offers several benefits in the realm of design and development. First and foremost, it allows teams to prototype and test their ideas quickly, ensuring that they are on the right track before delving deeper into the manufacturing process. This is especially valuable in the early stages of prototyping, where ideas are still being formed and perfectioned.

One of the primary goals of rapid prototyping is to produce a functional prototype that closely resembles the envisioned final product. Using methods like 3D printing and additive manufacturing, teams can create high-fidelity prototypes that give stakeholders a tangible sense of what the finished product will be like. Moreover, rapid prototyping isn’t merely about creating objects; it’s about iterating and refining designs based on feedback, ensuring that the final product meets user needs and expectations.

However, it’s essential to understand that rapid prototyping is not intended as a replacement for comprehensive product design or development processes. Instead, it offers product managers a chance to swiftly generate and validate new ideas in a cost-effective manner. By enabling teams to pinpoint potential issues and gather feedback early on, the risk of costly revisions down the line is significantly reduced.

Types of rapid prototyping

The world of rapid prototyping is diverse, with various methods and techniques tailored to different needs. Some of the common forms include:

- Paper Prototyping: This is one of the simplest forms used for rapid prototyping. It involves creating hand-drawn representations of user interfaces or product designs. While it may not look like the final product, it’s useful in the initial stages to gather feedback on design layouts and flows.

- Wireframing: A digital evolution of paper prototyping, wireframing involves creating skeletal layouts of digital interfaces. It helps in visualizing the structure and layout of a digital product.

- Digital Prototyping: This involves creating a virtual, functional prototype using software tools. It often looks and feels much like the final product and can be interactive, allowing for user testing.

- 3D Printing: A method where rapid prototyping involves using additive manufacturing to create a physical representation of the product. Especially useful when the final product is a tangible object and when the goal of rapid prototyping is to evaluate the physical attributes of a design.

Each type of rapid prototyping has its unique advantages and disadvantages. Understanding these will help teams and individuals select the method best suited to their specific needs, ensuring that the process is as efficient and effective as possible.

How does rapid prototyping work?

Rapid prototyping is used to swiftly create a physical part or assembly using design tools. The process typically begins with designers and engineers developing a digital design of the product, often using computer-aided design (CAD) software. This digital layout acts as a blueprint for the prototyping process, detailing the product’s dimensions, aesthetics, and functionalities.

Once the design is finalized, the next step involves translating this design into a physical part or assembly. Unlike traditional manufacturing methods, which often involve lengthy tooling and setup times, rapid prototyping allows for the direct creation of the product from the digital design. Techniques such as 3D printing, rapid tooling, and other advanced prototyping techniques are employed to bring the design to life.

Throughout this process, designers and engineers have the flexibility to iterate and refine the product, making adjustments based on feedback and testing. This iterative nature is one of the core benefits of rapid prototyping, ensuring that the final viable product closely aligns with the envisioned design and user needs.

Rapid prototyping process VS the traditional prototyping process

While both rapid prototyping and traditional prototyping aim to create a tangible representation of a product, the methods and philosophies behind them differ significantly.

Traditional prototyping often relies on conventional manufacturing methods, which can be labor-intensive and time-consuming. For instance, creating a prototype might involve manually crafting a model or setting up complex machinery to produce a single part. This approach can be effective for certain projects, but it often leads to longer lead times and limited flexibility in terms of design iterations.

On the other hand, the rapid prototyping capitalizes on advancements in technology to expedite the creation of prototypes. As mentioned earlier, digital designs can be directly translated into physical products without the need for extensive tooling or setup. This not only reduces the time taken to produce a prototype but also offers unparalleled flexibility. Designers can make changes on the fly, and multiple iterations can be produced in the time it might take for a single prototype using traditional methods.

Moreover, the collaborative nature of rapid prototyping fosters a more integrated approach, with designers, engineers, and stakeholders working closely to perfect the design. This collaborative spirit, combined with the speed and precision offered by modern prototyping tools, highlights the stark contrast and advantages of the rapid prototyping process over its traditional counterpart.

Getting started with rapid prototyping

Diving into the world of rapid prototyping can be both exhilarating and daunting, especially for those new to rapid prototyping. To achieve optimum results, a foundational understanding of best practices is essential. Here’s a brief guide to getting started:

- Set Clear Goals and Objectives: Before beginning, it’s crucial to clearly define what you aim to achieve with rapid prototyping. Whether it’s testing a specific feature, validating a design concept, or creating a minimum viable product, having a clear objective will guide the process effectively.

- Iterative Approach: Rapid prototyping enables a swift development cycle. Embrace an iterative approach, where designs are constantly refined based on feedback and testing. This iterative nature ensures that the final version of a product is well-aligned with user needs and expectations.

- Choose the Right Tools: With a plethora of prototyping tools available, from software prototyping applications to 3D printers, selecting the right tool for your needs is paramount. The choice often depends on the prototype’s complexity and the desired fidelity.

- Understand Materials: If you’re creating a physical part or assembly using computer-aided design, it’s essential to familiarize yourself with different prototyping materials. Each material has its properties, strengths, and limitations, influencing the prototype’s functionality and aesthetics.

- Streamline the Process: Utilize techniques and technologies that can help expedite and streamline the prototyping process. This might involve using premade design templates, modular components, or automation tools.

The convergence of rapid prototyping and 3D printing

One of the most transformative advancements in rapid prototyping has been the integration of 3D printing technologies. Unlike traditional subtractive methods, where material is removed to create a part, 3D printing is an additive process. It involves layer-by-layer construction to create a 3D part or assembly using computer-aided design data.

The synergy between rapid prototyping and 3D printing is evident. Using 3D printing, designers and engineers can swiftly translate digital designs into tangible, 3D printed parts. This allows for immediate feedback, multiple iterations, and the creation of complex geometries that might be challenging with traditional methods.

Moreover, 3D printing offers flexibility in terms of materials. From plastics and metals to ceramics and even biological materials, the range of prototyping materials available for 3D printing is vast. This material diversity ensures that the prototype not only looks like the intended final product but also behaves like it in terms of strength, flexibility, and other properties.

In essence, as rapid prototyping continues to evolve, the convergence with 3D printing technologies is amplifying its capabilities, making it an indispensable tool in modern product development.

Final thoughts

As the landscape of product design and development continually evolves, the importance of rapid prototyping becomes even more pronounced. Its ability to streamline processes, foster innovation, and reduce time-to-market is invaluable in today’s competitive environment.

With tools like 3D printing further enhancing its capabilities, the future of rapid prototyping looks brighter than ever. If you’re keen to explore another fascinating aspect of rapid prototyping, we encourage you to learn about CNC rapid prototyping here.