Stainless Steel CNC Machining: Advantages, Challenges, and Top Alloy Choices

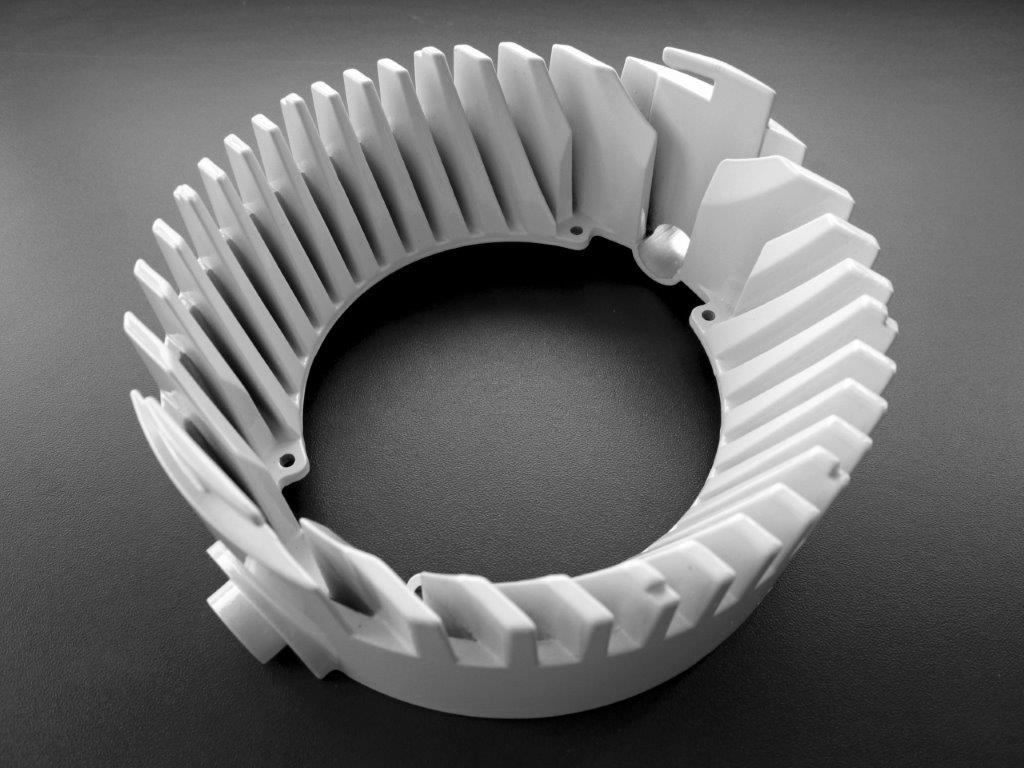

Renowned for its strength and durability, stainless steel is a popular choice for a wide range of applications — and with our CNC machining service, we can transform this versatile material into custom parts capable of withstanding harsh conditions.

This blog explores the advantages of stainless-steel CNC machining, the best alloy options, and potential challenges. Understanding these factors lets you determine if stainless steel is the ideal material for your specific project.

Why use CNC machining to make stainless steel parts?

CNC machining is a tried-and-true manufacturing method for making custom metal parts from a billet or block of your preferred metal. Stainless steel is in demand for its relatively hard nature. Moreover, heat treatments can improve its mechanical strength. This is why CNC machining services are ideal for making stainless steel parts exposed to high temperatures and corrosive environments.

Challenges of creating CNC-machined stainless steel parts

While stainless steel offers desirable properties like high machinability, hardness, temperature resistance, and strength, it also presents certain challenges during machining. Austenitic stainless steel, in particular, can “work harden,” which can lead to increased tool wear and reduced part quality.

Additionally, stainless steel’s lower thermal conductivity can cause heat to build up during machining. Insufficient cooling and improper cutting parameters can result in sensitization, a condition that can lead to stress corrosion cracking or intergranular corrosion, depending on the specific application of the part.

You don’t have to worry, however, because our expert machinists have access to the right tools and equipment to create CNC-machined stainless steel parts. We can recommend the best alloys based on your project and application.

- SS 303: Readily available and easy to machine, with good corrosion resistance for applications like aircraft fittings, electronic hardware, screws, bushings, and nuts and bolts.

- SS 416: Offers outstanding machinability with good strength and moderate corrosion resistance, making it ideal for pump shafts, valves, and gears.

- SS 304: The most common stainless steel alloy that is weldable and machinable. It’s versatile for various applications, such as heat exchangers, automotive parts, screws, and food-handling utensils.

Choose our CNC machining service here at HLH Prototypes for a worry-free project. Contact us today for a quote so we can review your needs and provide tailored design tips. You may also call us at +86 755 8256 9129.