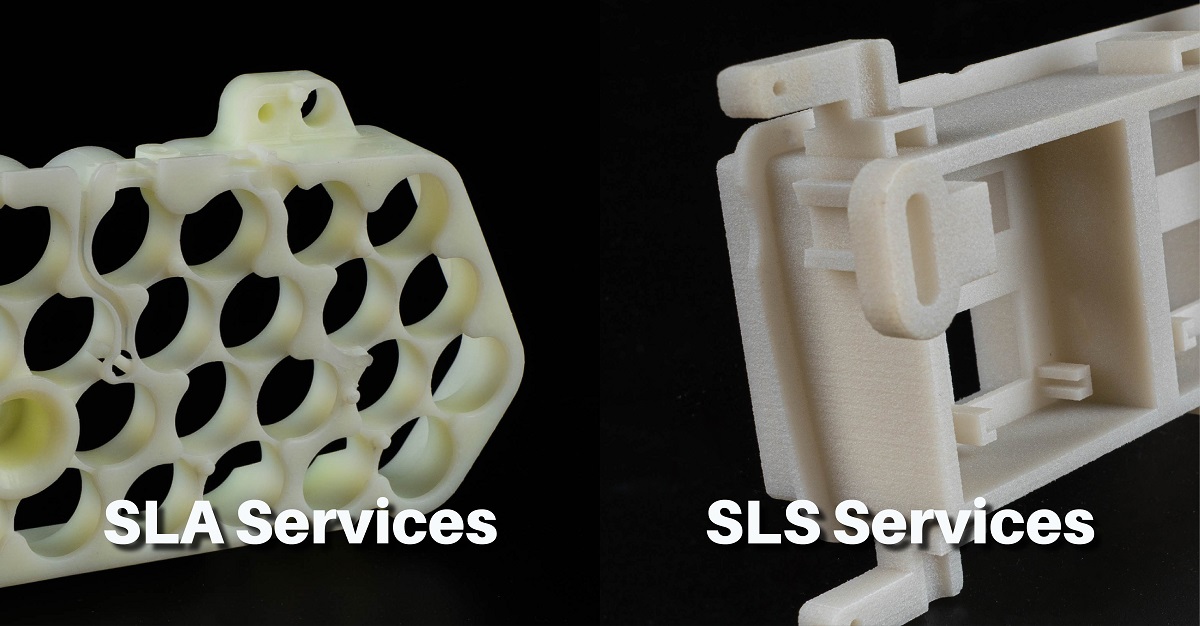

Are SLA Services and SLS 3D Printing Services the Same Thing? What are the Differences?

When considering additive manufacturing or 3D printing for your project, you’ll likely discover different technologies that can produce your prototype or end-use part. Two of them are SLA and SLS 3D printing services. While they share a few similarities, such as using a precise laser to build parts one layer at a time, they have significant differences worth knowing and comparing, so you can determine which is best for your project.

Differences in SLS and SLA 3D printing

SLA stands for stereolithography, and it uses a precise laser to cure a liquid resin in a build chamber. SLS stands for selective laser sintering, and it uses a laser to fuse powdered nylon material to create robust and accurate parts.

Applications

SLS 3D printing services are ideal for low-volume end-use parts and building functional prototypes. Consider SLA 3D printing if you’re building accurate aesthetic models or for rapid prototyping applications.

Feature definition and sizes

SLA may be the better choice when considering feature definition as it can be well-defined and smaller features. Some SLA 3D printing systems are high-resolution and can print smaller parts with finer details. However, if you don’t mind a grainy surface for your product, then SLS may be for you.

SLA also has more edge in feature sizes, especially when printing small features at higher resolution. However, SLS has the benefit in that the surrounding powder eliminates the need for support material while building the part. SLA additive manufacturing requires support material for building complex geometries or features.

Post-processing

Both SLA and SLS 3D printing services require some degree of post-processing. SLA-printed parts need to go through a post-curing process as well as a cleaning process to eliminate uncured resin after removing the supports. SLS requires excess powder removal. Both processes can be painted, machined, or sanded to enhance the part’s surface finish and minimize the appearance of layers.