Don’t get cornered – CNC machining tip

October 24, 2018

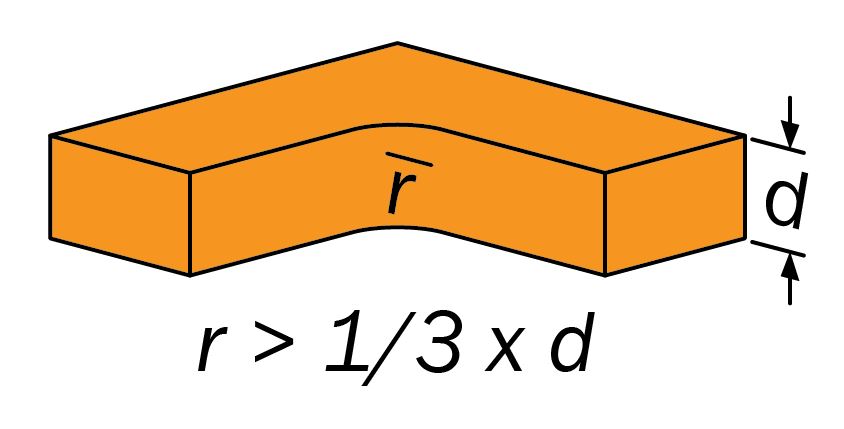

Many parts that are designed for CNC machining will have features such as pockets and cavities that will have corners that need machining. These corners will be rounded to a certain degree because the drill bits used for CNC machining are round. The rounder you can make your corners (without adversely affecting your design), the better your end use part will be. Knowing that here are some guidelines that will help you understand further.

The radius in any corner should be minimum 1/3 x the cavity depth and greater when possible. If you can increase your radii slightly above this recommendation then the CNC machine may be able to work in a circular path compared to a 90 degree angle. Your end result will be an improved surface finish in the corners of your part.

For floor radius, 0.5mm, 1mm, and no radius are all feasible as many CNC drill bits are flat on the end. But it is always bestt to check with your supplier to see if your design lines up well with the equipment they have for CNC machining your part. You may find that slight adjustments to corner radii and floor radii will end up producing a superior surface finish as well as saving you time and money.

Follow this design tip and other tips coming up to achieve a part design that is well suited for CNC machining. Below is some further CNC machining guidance which may help you with designing a successful part for CNC machining.

HLH Max CNC Machining Size: 3000x1200x850mm

Advantages

High speed

High dimensional accuracy

Great surface finish

Wide material selection

High volumes

Rapid prototypes

Drawbacks

It can be expensive for complex

parts and for larger parts.

Tolerances: ISO 2768-1 states the tightest tolerances possible as standard are +/- 0.05mm for metals or +/- 0.2mm for plastics. Tighter tolerances should be discussed case by case.

Surface Finishes

Polishing

Sand blasting

Painting

Plating & More

Popular Materials

Plastic ABS, PC, Acrylic

Metal SS304, 316

Aluminium 6061, 7075

Plus many more

Tips and Tricks

Radius internal corners

Loosen tolerances where possible

Keep features perpendicular to the six sides

Reduce the number of setups

Keep it simple