Guide to Sheet Metal Prototyping

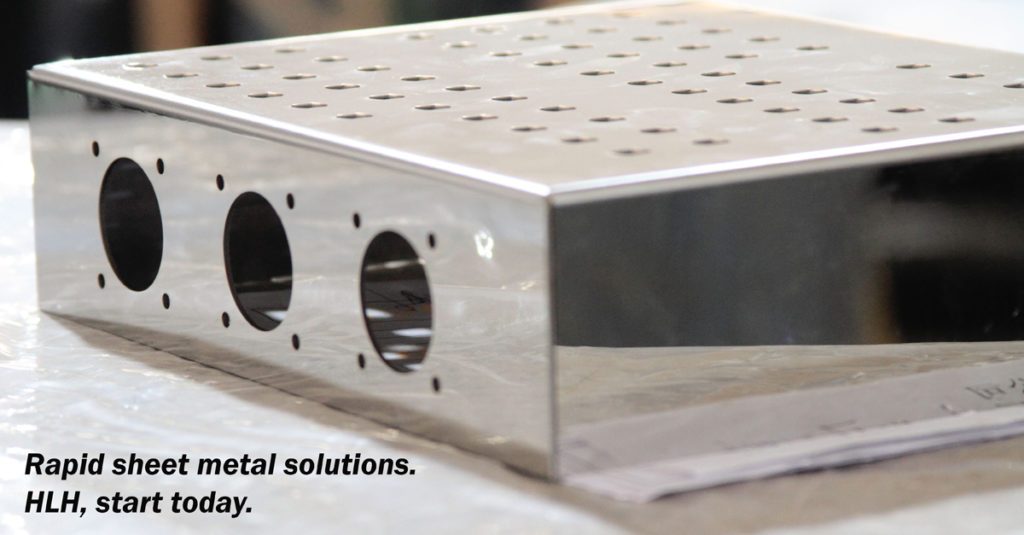

Sheet metal is a commonly used material for a wide array of products and processes. If you need it for your own project, sheet metal prototyping is a good way to develop enclosures, assemblies, brackets, housings, cabinets, weldments, and other parts or prototypes accurately and quickly. The process involves the manipulation and shaping of sheets of metal into the specific geometry that you require. Typically, it uses methods like punches, laser cutting, bending, and welding to manufacture your prototypes and parts. As long as you work with the right service provider, you’re almost certain to get high-quality and consistent results, making it ideal for a wide range of projects.

Sheet metal prototyping offers a cost-effective means to build parts and prototypes out of a durable, hard-wearing and inexpensive materials. Reputable service providers have their own equipment and an in-house team of technicians and machine operators to ensure the quick delivery of results. Some of their most common customers are manufacturers of products in the communications and medical industries, alongside people who produce computers, enclosures, and housings.

Sheet metals come in an array of types of sizes, so you should be able to find the perfect material for your project. They include hot-rolled and cold-rolled steel plates, aluminum sheets, stainless steel plates, copper plates, and galvanized steel sheets. The process of sheet metal prototyping involves skilled designers and engineers working on various blueprints for the parts to ensure that they meet acceptable allowances and tolerances. Those parameters ensure that the fabrication is successful, and allow the sheet metal prototyping service to reproduce exact replicas of the CAD drawings.

Sheet metal prototyping can be customized to suit the unique requirements of your project. Some companies can cater to low and mid-volume production requirements. When in doubt, get in touch with them to have your project reviewed by their design team. This allows them to recommend the best solutions to your exact needs and ensure the prompt and speedy delivery of the prototypes to you. If you really want to keep the costs down, then you should try to avoid things such as bending radii, which generally make sheet metal prototyping more expensive.