How CNC Routers and Mills Differ in Function and Performance

Product designers and makers frequently rely on CNC machining services to create custom components. While both CNC routers and mills are integral to the CNC machining process, they offer different features, capabilities, and material compatibilities. A project will often benefit from utilizing both types of machines for optimal cutting performance.

The characteristics of CNC routers

CNC routers specialize in working with specific materials. While they are not suitable for cutting hard substances like titanium and steel, they excel at shaping softer materials such as plastic, as well as soft metals like aluminum.

Speed is one of the defining features of CNC routers. They operate faster than mills but have lower torque. The routers use rotational speed to generate force, making them effective for projects where multiples of a part need to be produced quickly. If your CNC machining services are geared towards rapid but consistent manufacturing, routers may be the better option. While they have higher RPMs, they are not suitable for industrial-grade materials. That’s where mills come into play.

The capabilities of CNC mills

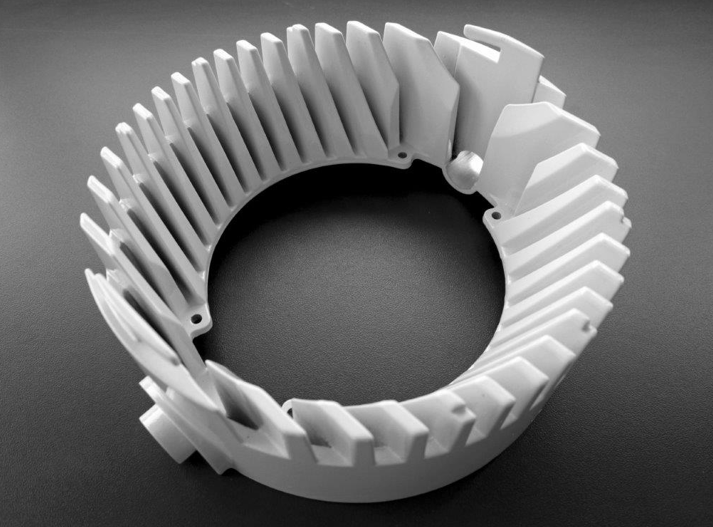

In contrast, CNC mills are the go-to choice for high-precision and heavy-duty tasks, as they can cut harder materials like titanium, steel, and aluminum. They are also capable of achieving more intricate cuts, often to within 1,000th of an inch. This level of precision is due to the unique way the machine’s axes are configured.

Unlike routers, where the material stays fixed and only the cutting bits move, mills shift the workpiece along linear axes. This allows for more complex designs and thicker cuts, making CNC mills preferable for tasks that require higher precision and durability.

Choosing the right machine for your project

Determining whether your project requires CNC routers, mills, or a combination of both is easier when you consult with experts. At HLH Prototypes, you can learn more about our CNC machining services by requesting a quote and a project review. We can help guide you in selecting the most appropriate machinery and processes for your unique needs.