How Prototype Molds Can Help in Innovation

Plastics are common in many industries. Just take a look around you, and you’ll find them in various objects, including automotive parts, medical devices, electronics, and more. Innovations in plastic products have become widespread with proven manufacturing technologies like injection molding, which involves custom prototype molds to produce high-volume, virtually identical parts quickly and cost-effectively.

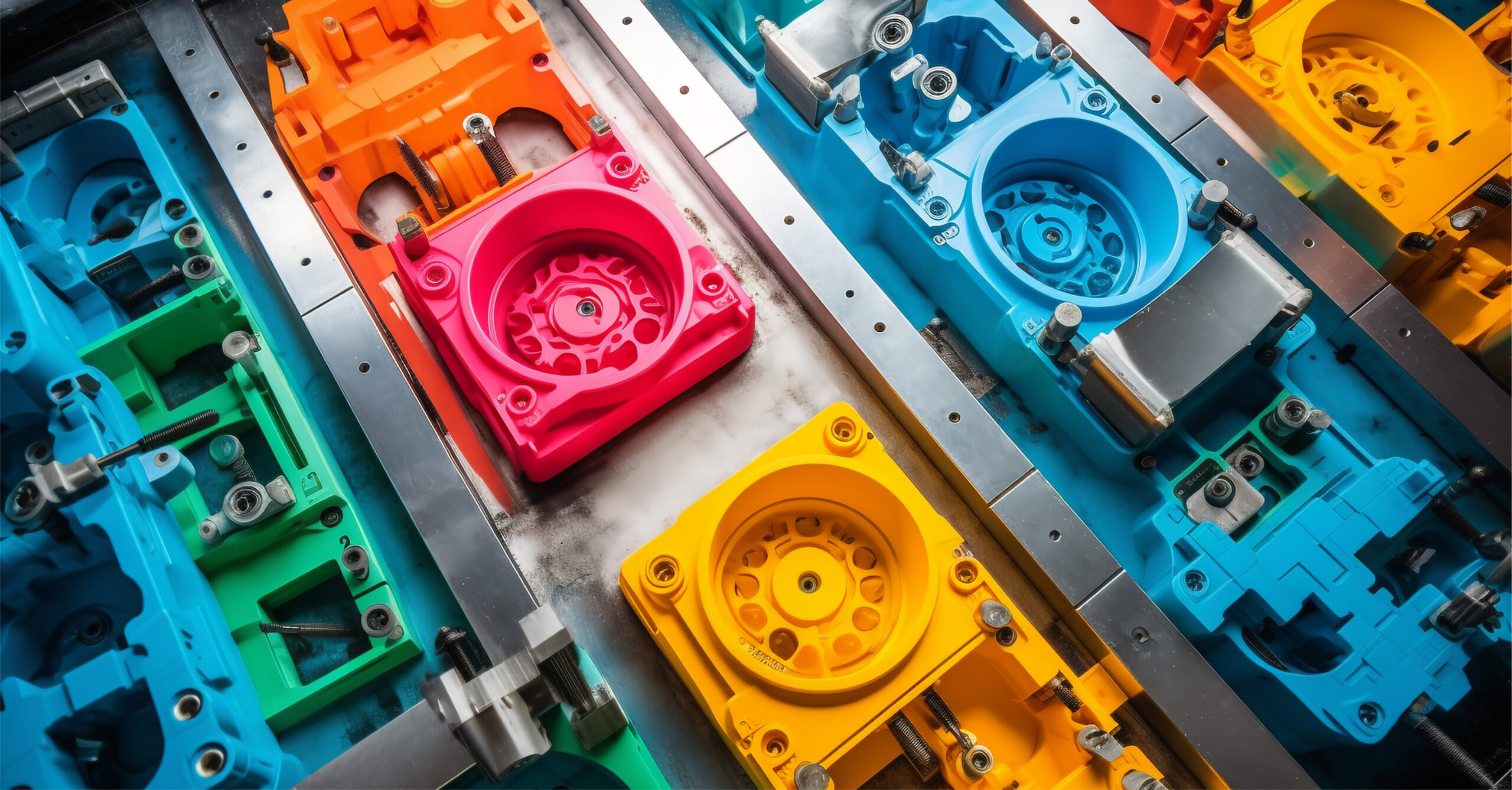

Injection molding is one of the widely used plastic manufacturing and prototyping processes. It involves melting plastic polymers to build parts fast. While under pressure, the molten plastic solidifies in custom molds until it forms a shape. The process is repeatable and can help manufacture hundreds and thousands of identical parts at a more reasonable cost. High-quality molds are reusable and allow you to produce multiple parts with complex dimensions or diverse shapes.

Pushing innovation and sustainability

Product design and development involve extensive planning and work to ensure high-quality end-use products for consumers. Plastics are reasonably priced, durable, and versatile materials, with higher-end ones offering excellent flexibility, exceptional strength, and eye-catching finishes.

Additionally, recyclable plastics ensure environmental sustainability. Plastic molding that involves prototype molds uses a closed-loop industrial process that helps reduce waste. Moreover, it ensures precise results that eliminate the need for rework. As such, it also reduces the product development cycle time.

Increase your production efficiency.

Prototype molding is known for efficiency and speedy production rates, with a high production output that delivers cost savings and the possibility for low-volume production of around 100,000 parts. And because it’s repeatable, scrap rates are lower compared to other manufacturing processes. One steel or aluminum mold could produce hundreds or thousands of parts before it reaches the end of its lifespan. Aluminum molds can withstand as much as 10,000 cycles, and high-quality steel molds can survive over 100,000.

Innovate with injection molding today.

Our team here at HLH Prototypes will create your prototype molds using injection molding. Contact us to get started with a free project review and quote to learn more about our service and its value to your product development.