How Vacuum Casting in China Enhances Prototyping

If you’re trying to speed up development and keep costs in check, vacuum casting in China (also known as urethane casting) is a fast and flexible method for producing high-quality prototypes — without the long lead times or high costs of traditional tooling.

At HLH Prototypes Co. Ltd, we use vacuum casting to create parts that are ideal for functional testing, engineering reviews, and even display models for marketing or crowdfunding campaigns.

Faster than traditional tooling

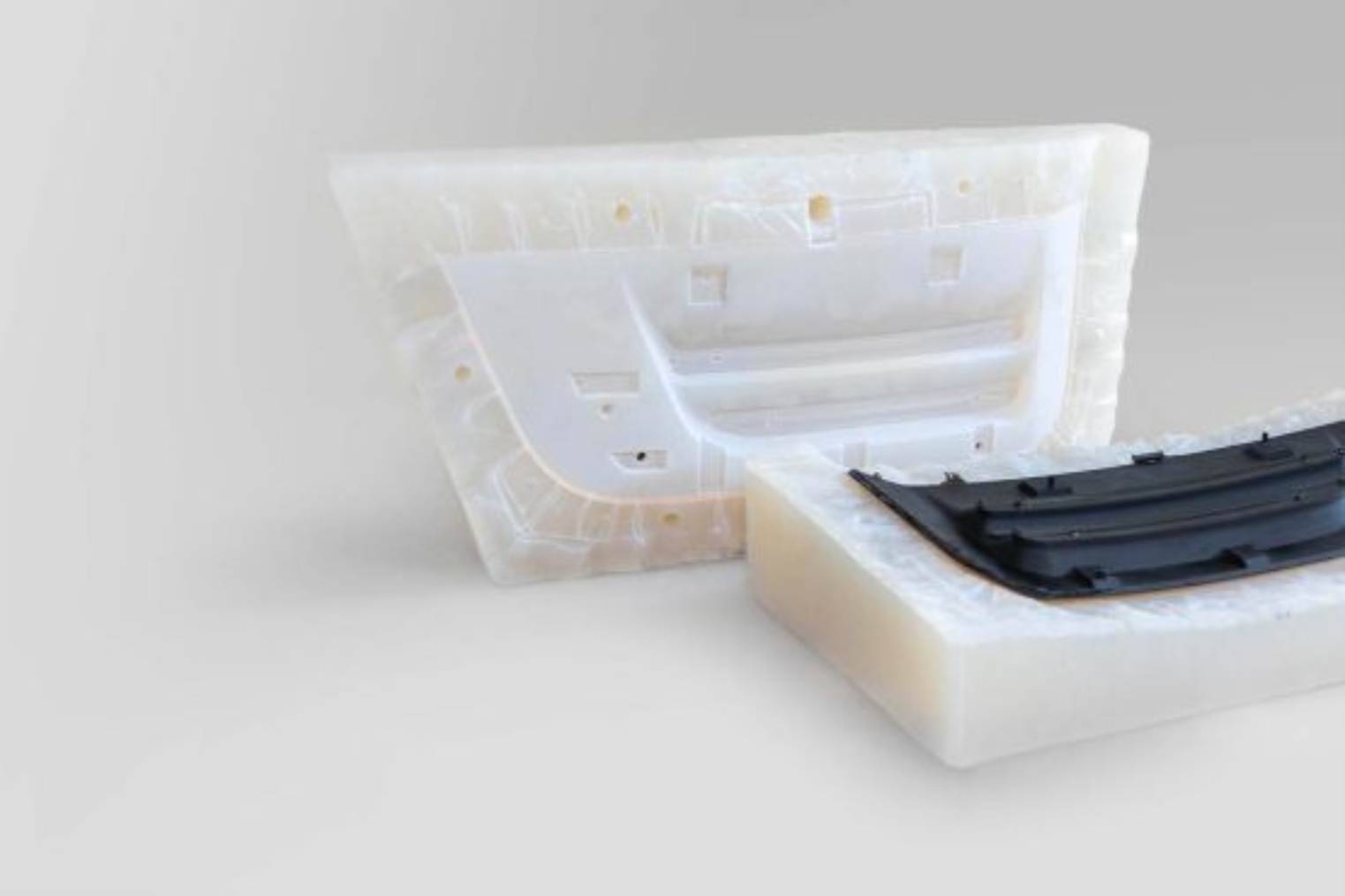

Vacuum casting in China is faster than traditional manufacturing because it skips the time-consuming process of making hard production tooling. Instead, it uses a master model—often made with 3D printing or CNC machining—to create a silicone mold. Once the mold is ready, it can be used to produce multiple identical parts quickly with minimal setup. This makes it a much faster option for low-volume production and rapid prototyping.

Cost-effective for low-volume production

Vacuum casting in China can save you money if you only need a small batch of identical parts. The cost per part drops as volume increases, and there’s no need to invest in hard tooling. Plus, the process supports a wide range of materials, from rigid plastics to soft, flexible rubbers, giving you the freedom to match material performance with your design needs.

High-quality, functional results

Vacuum casting delivers detailed, smooth-finish parts that closely mimic the quality and performance of production-grade components. These prototypes are strong enough for functional testing and durable enough for real-world use.

Wondering if vacuum casting is right for your project?

Share your project with our team here at HLH Prototypes Co. Ltd for a free review. You can also call us directly at +86 755 8256 9129. We’ll help you decide whether vacuum casting in China is the right choice for your project.