Injection Molding Tips – Part 1

October 31, 2018

Your part design will likely need slight variations depending on the manufacturing process you choose. Each manufacturing process has a set of rules that are unique and should be followed to help save you time, money, and to ensure a much better end product.

We continue injection molding week here at HLH with a couple of tips for your consideration as you are designing your next part for manufacturing via injection molding. More tips coming this week 🙂

Draft – draft angles should be added to all parts in the direction of draw. Draft prevents surface scratches and damage when demolding and prolongs the life of the tool. Two degrees’ draft + is recommended. There are times that you can get away with less draft but whenever possible try to design with the recommended two + degrees.

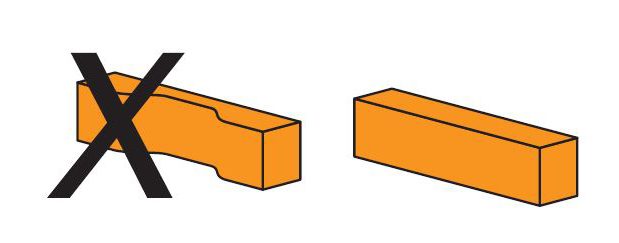

Wall thickness – use uniform wall thicknesses. Walls 1-3mm are recommended for most materials.

Follow these design tips and other design tips coming up to achieve a part design that is well suited for injection mold manufacturing. Below is some further injection molding guidance which may help you with designing a highly successful part for injection molding manufacturing.

HLH Machine Sizes – 80 to 3000 ton

Advantages

Low cost per part

Repeatable

Large selection of materials

Good surface finish

Drawbacks

Requires investment in tooling

Longer lead time to first parts

Surface Finishes

Textured in tool

Coloured in tool

Painted or Plated

Silk/pad printed

Materials

Too many to list. Talk

to HLH to find out

material options for

your project.

Tips and Tricks

Remove undercuts if possible

Specify a lower grade surface finish

Mold in standard plastics – pp, abs etc

Reduce weight of part