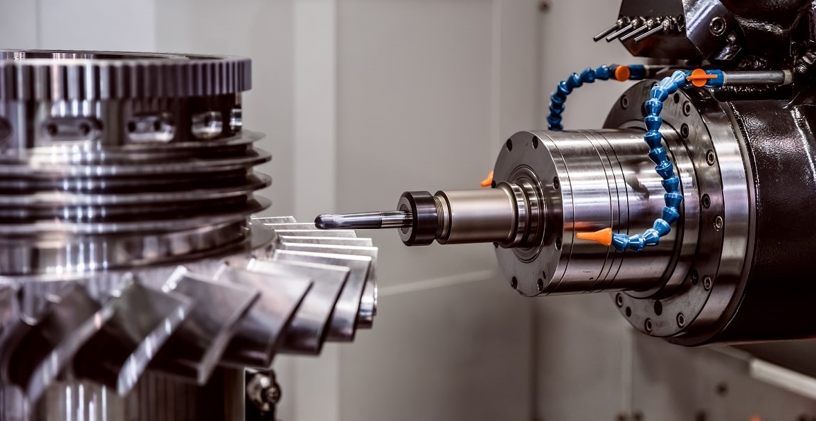

How Precision CNC Machining is Revolutionizing Modern Manufacturing

Understanding CNC Machining

CNC (Computer Numerical Control) Machining is a process used in modern manufacturing that involves the use of computers to control machine tools. This section provides an introduction to CNC machining and highlights the advantages of precision CNC machining.

Introduction to CNC Machining

CNC Machining stands at the forefront of manufacturing technologies, transforming the way components are produced. Through CNC machining services, manufacturers can create complex parts with high precision by programming machines to execute a series of precise movements. This method employs specialized software and code, such as G-code, to guide tools in fabricating items from various materials.

The process encompasses a range of operations including turning, milling, and drilling, which can all be performed by CNC machines. It’s a pivotal technology that caters to various industries, enabling the creation of intricate designs that would be difficult or impossible to achieve with manual machining. For a comprehensive understanding of the technology, readers are encouraged to explore what is CNC machining.

Advantages of Precision CNC Machining

Precision CNC machining brings numerous benefits to the table, revolutionizing the manufacturing process through its accuracy, efficiency, and safety. The following are some of the key advantages:

- Reduced Waste: CNC machining is highly efficient, producing minimal waste material. Programs optimize the manufacturing process to use materials effectively, leading to significant waste reduction.

- Zero Defects and Greater Accuracy: The automated nature of the CNC machines allows for unparalleled precision, virtually eliminating defects. Consistency is maintained throughout production, ensuring that every component meets stringent quality standards (TFG USA).

- Scalable Production: With the ability to operate continuously and maintain accuracy, CNC machines facilitate scalable production without sacrificing quality. This allows manufacturers to meet high demand efficiently.

- Enhanced Safety: CNC machines enhance worker safety by operating autonomously, reducing the need for direct human interaction with dangerous equipment. This minimizes the risk of accidents in the workplace.

- Versatility: Precision machining can produce components with high tolerances and excellent surface quality. It is versatile enough to include a combination of various manufacturing processes, catering to the needs of different industries.

In summary, precision CNC machining offers a range of benefits that make it a valuable asset in modern manufacturing. From creating intricate parts with high precision to ensuring consistent quality and reducing material waste, it’s clear why this technology is embraced by manufacturers worldwide. As the industry evolves, understanding the types of CNC machines and their capabilities will be crucial for those looking to invest in CNC machining services.

Types of CNC Machines

Precision CNC machining encompasses a range of machines, each specialized for different manufacturing tasks. Understanding the capabilities of each type of CNC machine is crucial for those looking to procure CNC machining services. Here, we delve into the specifics of CNC turning, milling, and drilling machines, which are integral to the modern manufacturing landscape.

CNC Turning Machines

CNC turning machines, also known as lathes, are designed to rotate a workpiece on its axis to perform various machining operations such as cutting, sanding, knurling, drilling, or deformation. These machines are highly efficient at producing cylindrical parts with precise measurements.

According to TFG USA, precision turning machines operate autonomously, which leads to zero defects and greater accuracy. The use of computer codes and software programs ensures consistent and flawless production without human errors.

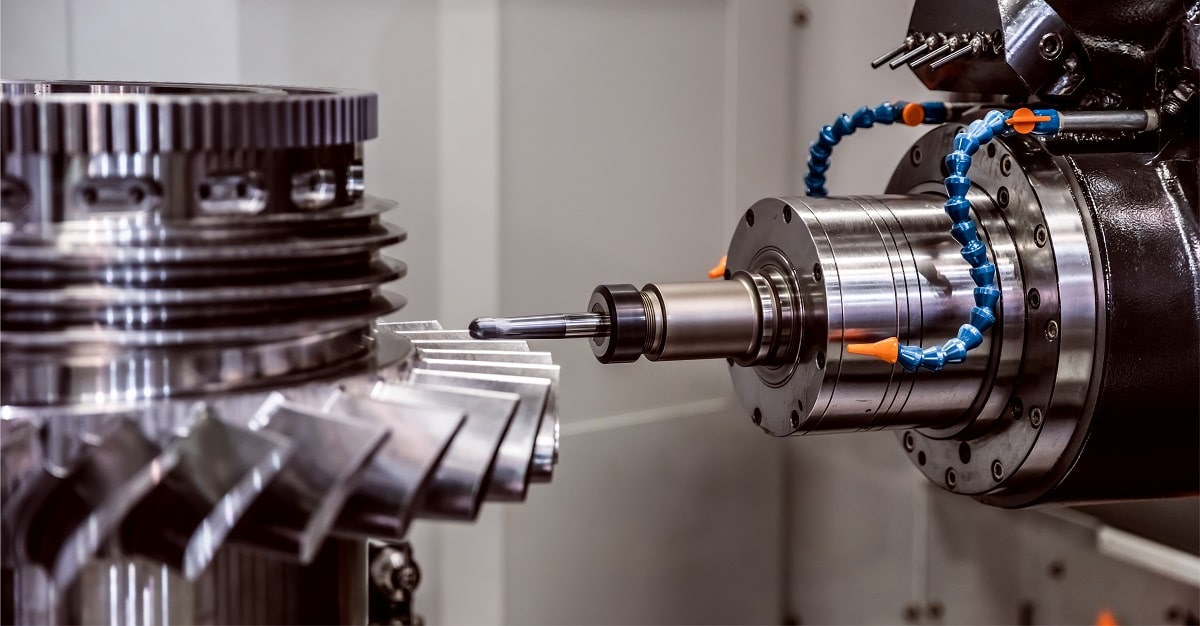

CNC Milling Machines

CNC milling machines are versatile and widely used in precision CNC machining. They remove material from a stationary workpiece with a rotating cutting tool to produce a desired shape. Milling machines can perform a variety of operations, from simple cuts to complex shapes, and are excellent for projects that require high precision and repeatability.

CNC machining is typically the most cost-effective method for adding mounting surfaces, holes, screw threads, and precision bores into parts that are either cast or machined from solid. This is particularly true for high-quantity projects where consistency and accuracy are paramount (Impro Precision).

CNC Drilling Machines

CNC drilling machines are specialized for making cylindrical holes in a workpiece. They can also perform other operations such as reaming, countersinking, and counterboring. These machines work by advancing a drill bit into a stationary workpiece, and they are highly effective when precise holes are needed.

Drilling machines, like all CNC equipment, benefit from the advantages of CNC machining over conventional methods, including superior precision, speed, production rate, and accuracy. They are crucial for projects that demand the drilling of numerous holes with exacting specifications (Sheldon Precision).

Each type of CNC machine brings its own set of capabilities to the manufacturing process, and understanding these can help in selecting the right CNC machining service for your project. Whether for turning, milling, or drilling, precision CNC machines are essential tools in achieving the high standards expected in today’s manufacturing sectors. For more detailed information on CNC machines and their applications, consider exploring our comprehensive guide on what is CNC machining and the various types of CNC machines available.

Importance of Precision in CNC Machining

Precision in CNC (Computer Numerical Control) machining is a critical factor that sets it apart from traditional manufacturing techniques. The intricacy and accuracy of the final product depend heavily on the precision of the machining process.

Achieving High Precision

Achieving high precision involves controlling the position and movement of cutting tools, workpieces, and machine components to meet exact specifications. This precision ensures that the dimensions, surface finish, and tolerances of manufactured parts are produced accurately and consistently. As Fadal explains, high levels of precision in CNC machining are essential to minimize the risk of product failures and safety hazards, which, in turn, ensures that the final product meets the highest quality standards.

Precision CNC machining utilizes advanced computerized systems to dictate the operation of the tools. The precise control over the cutting parameters, such as speed, feed rate, and coordination, enables the machine to produce complex shapes and designs that would be difficult or impossible to achieve manually. Here are some key factors that contribute to achieving high precision in CNC machining:

- Advanced software for precise programming of the machine’s movements.

- High-quality cutting tools that provide clean and accurate cuts.

- Rigorous calibration of machines to maintain alignment and reduce errors.

- Skilled technicians who can optimize the machine settings and troubleshoot issues.

Ensuring Consistency and Accuracy

Consistency and accuracy are the hallmarks of CNC machining services, which streamline production by minimizing human error, fatigue, and variations. According to JLC3DP, the automated precision and reproducible outcomes of CNC machining ensure a consistent high standard of parts produced. This consistency is vital in industries where the slightest deviation can lead to significant consequences.

CNC machining also offers long-term time and cost savings. While the initial setup and programming may require time and resources, the efficiency and automation of the process lead to reduced labor costs, minimized material waste, and a decreased need for subsequent processes. The table below illustrates the benefits of CNC machining compared to traditional methods:

| Benefit | CNC Machining | Traditional Machining |

| Precision | High | Variable |

| Consistency | Repeatable | Depends on operator |

| Efficiency | High | Lower |

| Labor Costs | Reduced | Higher |

| Waste | Minimal | Higher |

For applications that demand superior surface finishes, such as aerospace or medical components, CNC machining’s capability to produce high-quality finishes is unmatched. The computer system’s control over optimal cutting parameters and tool trajectories results in a level of surface finish that traditional methods cannot consistently achieve.

In sum, precision CNC machining is crucial for modern manufacturing, offering unparalleled consistency and accuracy. For those seeking CNC machining services, understanding the significance of precision is key to selecting the right service provider. As you delve deeper into the world of CNC machining, learn more about what is CNC machining and the types of CNC machines to appreciate the technological advancements that continue to revolutionize manufacturing.

Applications of CNC Machining

Precision CNC machining has revolutionized various industries with its ability to produce high-quality, precise parts and components. From the automotive sector to healthcare, CNC machining plays a pivotal role in manufacturing.

Automotive Industry

In the automotive industry, precision CNC machining is utilized for producing an array of precision metal parts, particularly for engine and transmission components. It is celebrated for its accuracy and repeatability, making it an indispensable part of automotive manufacturing processes. CNC technology offers advantages at every stage, from prototyping to the production of large quantities of components. Machines such as CNC milling machines and lathes are employed to craft engine block parts, gears, and panels, handling various materials including plastics and metals (3ERP).

Aerospace and Defense Industry

The aerospace and defense industries demand the highest level of precision and reliability, which is where CNC machining comes in. The ability to work with difficult-to-machine metal alloys, such as high-strength steel, is crucial in producing parts for aircraft and military equipment. The stringent requirements of these industries for parts that can withstand extreme conditions are met effectively by the capabilities of CNC machining (Spex Precision Machining).

Healthcare Industry

CNC machining’s precision is vital in the healthcare industry, where the manufacturing of medical devices must adhere to strict standards. The technology is used in the production of medical supplies, rapid tooling, and the creation of intricate parts such as bone screws and plates. These components require smooth surface finishes to ensure patient comfort and safety, a hallmark of CNC machining’s capabilities.

Each of these industries benefits from CNC machining’s ability to deliver high-quality, precise, and consistent results. As technology continues to advance, the applications of CNC machining are set to expand even further, solidifying its role in modern manufacturing. For more information on the types and capabilities of CNC machines, readers can explore types of CNC machines and understand what is CNC machining in greater detail on our site.

Choosing a CNC Machining Service

Selecting the right CNC machining service is a pivotal decision that can impact the success of your manufacturing project. When evaluating potential partners for precision CNC machining, it’s essential to consider their expertise, track record, and commitment to quality.

Expertise and Track Record

The expertise of a CNC machining service provider is often reflected in their track record. An experienced provider will have a well-documented history of successful projects and satisfied clients. This experience is indicative of their ability to handle diverse machining needs and to reduce errors, ensuring a smoother and more efficient process. When researching potential services, look for information about the types of projects they have completed and the range of clients they have served. This will give you valuable insight into their capabilities and level of expertise (3ERP).

It’s also beneficial to examine the provider’s industry presence and reputation. Reviews, testimonials, and case studies can provide a clearer picture of their reliability and the quality of their work. Here are some aspects to consider:

- Years of operation in the CNC machining industry.

- Range of services offered, including specialized capabilities.

- Types of industries served and project complexity handled.

- Client testimonials and case studies showcasing their work.

Quality Control and Certifications

Quality assurance is a critical aspect of CNC machining. Certifications such as ISO 9001 are indicators of a service provider’s dedication to high quality and consistent outcomes. A reputable CNC machining service will have rigorous quality control measures in place to ensure that each component meets the required specifications and industry standards.

When assessing a CNC service, inquire about their quality assurance processes and certifications. This can include:

- ISO and other industry certifications demonstrating adherence to quality management standards.

- In-house quality control procedures, such as regular equipment maintenance and calibration.

- Methods of inspection and testing used to verify part dimensions and tolerances.

- Processes for handling non-conformities and continuous improvement practices.

It’s advisable to partner with a service provider that prioritizes quality and has the necessary certifications to back up their claims. This commitment to excellence will help ensure that your CNC machining needs are met with precision and reliability. For an in-depth look at what to expect from high-quality CNC machining services, and to learn more about the process itself, visit our comprehensive guide on what is CNC machining. Additionally, understanding the types of CNC machines available can further inform your service provider selection, ensuring that they have the right technology and machinery to handle your specific project requirements.

Factors to Consider

When selecting CNC machining services, a number of critical factors must be taken into account to ensure that the final product meets the desired standards of quality and precision. Below are key considerations to bear in mind.

Machinery and Technology

Advanced machinery and technology are the backbones of precision CNC machining. The use of computer-aided design (CAD) software is pivotal in achieving machining accuracy within .0001 inches, allowing for the consistent production of identical items. Moreover, the cutting tools directed by the software must be capable of high-speed manufacturing with complete automation to fulfill the demands of various manufacturing industries (3ERP).

It’s essential to verify that the CNC machining service provider is equipped with the latest technology and machinery, which are indicators of their ability to deliver high-quality and precise products. The provider’s expertise in utilizing these technologies also plays a crucial role in the manufacturing process.

Material Compatibility

The compatibility of materials with CNC machining processes is a critical consideration. Different projects require different materials, ranging from metals and plastics to composites and exotic alloys. It’s important to ensure that the service provider can work with the specific materials needed for your project and can make informed recommendations based on the project’s requirements (LinkedIn).

In industries such as construction, the need for reliable, high-strength metal parts is non-negotiable. Therefore, the service provider must be proficient in machining difficult-to-machine metal alloys, such as high-strength steel, which are often required in the manufacturing of construction equipment like cranes and bulldozers.

Quality Assurance Processes

Ensuring the quality of CNC machined parts is paramount. Quality assurance involves thorough inspection using metrology tools such as coordinate measuring machines (CMM) and laser scanners. These tools are essential for confirming dimensional accuracy and surface quality, minimizing deviations and defects.

Inquiring about the provider’s quality control processes and certifications is crucial. This ensures that the service adheres to high industry standards for quality management and is capable of delivering products that meet precise specifications (LinkedIn).

When considering a CNC machining service, it’s imperative to examine these factors closely. By doing so, you can align with a provider that has the machinery, material expertise, and quality assurance processes necessary to meet your manufacturing needs. Furthermore, exploring the types of CNC machines available can provide additional insight into what kind of equipment might be best suited for your project’s specific requirements.