Mastering the Art of SLA Rapid Prototyping: A Complete Guide to Revolutionizing Your Design Workflow

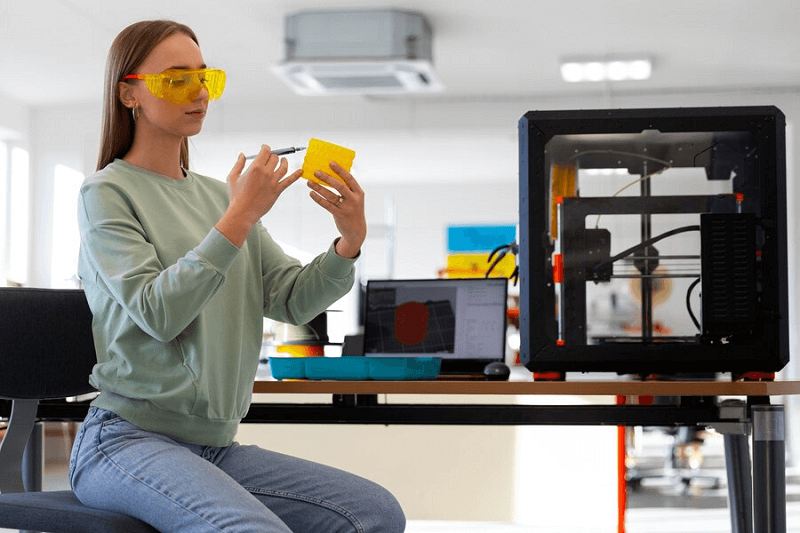

At HLH Prototypes, we offer a wide range of materials for SLA 3D printing to deliver the exact parts you need. Whether for prototyping or low-volume production, all we need is your CAD file, and we will take care of the rest. Stereolithography creates parts with a good surface finish but requires support structures to support them while building. We will remove the supports after printing and post-process the part when necessary.

While we strive to deliver parts quickly and cost-effectively, we want to help you maximize your design workflow to save time and minimize project costs. In this blog, we share a comprehensive guide to revolutionizing your designs for SLA rapid prototyping.

Printing tip: leave escape holes

Stereolithography can produce highly accurate-to-CAD parts, including complex geometries and shapes. When we provide a quote, we consider your part’s weight or volume. To reduce costs, we recommend hollowing out thicker sections of your design. However, it’s crucial to include “escape holes” for any uncured resin. This allows the remaining liquid resin to drain out during the post-curing process. Reducing the overall weight of your part can significantly lower production costs.

Ensure adequately sized walls.

We recommend making walls and other features at least 0.4 millimeters (mm) thick to ensure your design prints smoothly and accurately. This also helps maintain the printer’s resolution and prevents potential issues. Does your design include supported walls? Aim for a minimum thickness of 0.5 mm to enhance structural integrity and minimize the risk of warping during printing.

Create stronger parts

Consider filleting the corners of walls and pins for extra strength in your SLA rapid prototyping parts. This reduces the risk of breakage or warping, especially for unsupported walls. Aim for a wall thickness of at least 0.8mm to 1.00mm. Filleted bases at the wall joints help distribute stress more evenly and minimize the likelihood of failure.

Don’t forget to include supports in your design.

Overhanging features in SLA 3D printing generally require support structures for successful printing. While it might be technically possible to print overhangs less than 1.0mm long and at an angle greater than 19 degrees from the level without support, we strongly recommend using supports to minimize the risk of warping and ensure optimal print quality.

Talk to us!

Contact us here at HLH Prototypes for more design tips for SLA rapid prototyping! We will provide tailored advice and insights according to your project. Talk to us by calling +86 755 8256 9129. You may also get a quote and request a project review via chat or our online form.