Subtractive Manufacturing: What You Need to Know?

Subtractive manufacturing is a fundamental process in modern production, widely used in industries such as aerospace, automotive, and consumer goods. It involves shaping raw materials into precise finished parts by removing excess material.

HLH Prototypes specialize in providing high-quality subtractive manufacturing services, delivering accurate and reliable results for various applications.

In this article, we’ll explore what subtractive manufacturing is, how it works, its advantages, and how it compares to additive manufacturing.

What Is Subtractive Manufacturing?

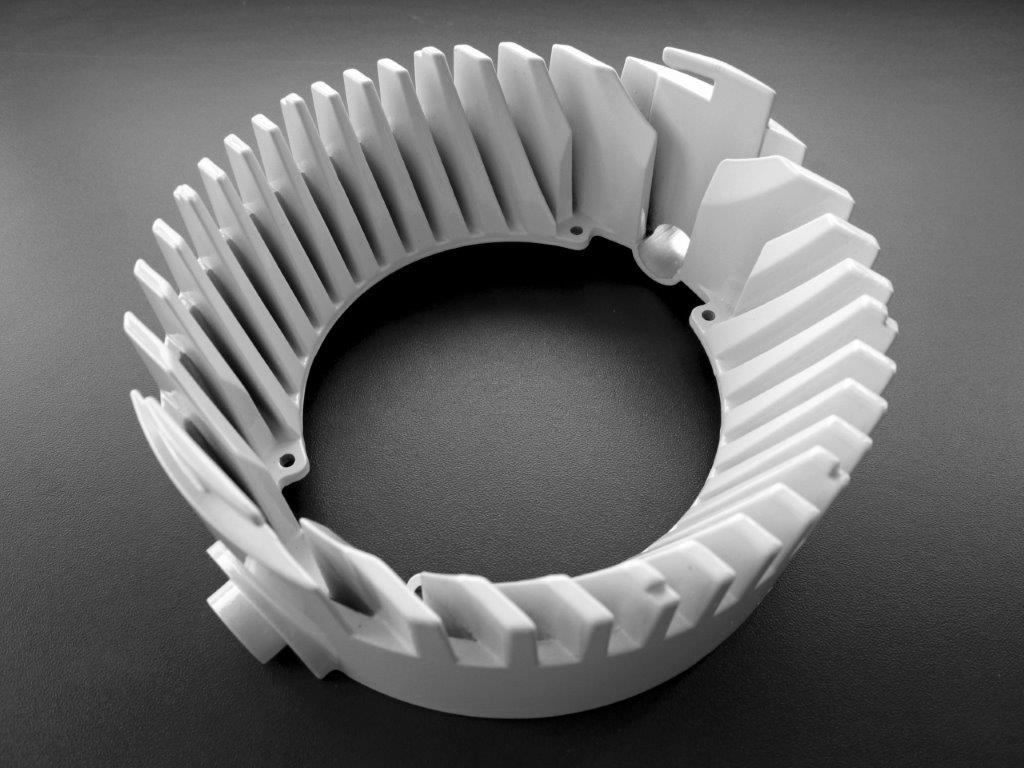

Subtractive manufacturing is a process where material is removed from a solid block, sheet, or rod to create a desired shape or design. This method uses tools such as cutters, drills, and lathes to achieve precise geometries. Common materials include metals, plastics, and composites. Unlike additive manufacturing, which builds parts layer by layer, subtractive manufacturing starts with a larger piece of material and removes excess to achieve the final form.

Key Processes in Subtractive Manufacturing

Subtractive manufacturing encompasses several techniques, each suited to specific applications:

1. CNC Machining/

CNC machining is one of the most popular methods in subtractive manufacturing. It uses computer-aided design (CAD) models to guide automated cutting tools. CNC machines can perform milling, turning, drilling, and grinding operations with exceptional precision.

2. Turning

In turning, a cutting tool removes material while the workpiece rotates. This process is ideal for creating cylindrical shapes like shafts, pulleys, and bushings.

3. Milling

Milling is the process of using rotating cutting tools to remove material from a stationary workpiece. It’s commonly used for complex shapes, slots, and holes.

4. Drilling

Drilling creates cylindrical holes in a workpiece using a rotating drill bit. This process is fundamental in industries requiring precise holes for screws, bolts, or fluid passage.

5. EDM (Electrical Discharge Machining)

EDM uses electrical discharges to remove material. It’s perfect for hard metals or intricate designs that are difficult to machine with traditional methods.

Advantages of Subtractive Manufacturing

Subtractive manufacturing offers several benefits:

- High Precision: Achieves tight tolerance, making it ideal for critical applications such as aerospace components.

- Material Versatility: Can process a wide range of materials, including metals, plastics, and ceramics.

- Surface Finish: Provides excellent surface quality, often eliminating the need for additional finishing processes.

- Scalability: Suitable for both prototyping and mass production.

Limitations of Subtractive Manufacturing

Despite its advantages, subtractive manufacturing has some drawbacks:

- Material Waste: Produces significant waste since excess material is removed.

- Complexity Limitations: Struggles with creating highly intricate geometries compared to additive manufacturing.

- Cost: Tooling and setting up can be expensive for small production runs.

Subtractive vs. Additive Manufacturing

While subtractive manufacturing involves material removal, additive manufacturing (3D printing) builds parts layer by layer. Each has its strengths and applications:

- Speed: Subtractive manufacturing is faster for simple designs, while additive manufacturing excels in producing complex parts without tooling.

- Cost: Additive methods are more economical for low-volume production or highly customized parts.

- Strength: Subtractive manufacturing often results in stronger parts due to the material’s continuous grain structure.

Applications of Subtractive Manufacturing

Subtractive manufacturing is widely used across various industries:

- Aerospace: Produces engine components, structural parts, and precision tools.

- Automotive: Creates gears, engine blocks, and prototype components.

- Medical: Manufactures implants, surgical tools, and dental prosthetics.

- Consumer Goods: Develops molds, prototypes, and final products with high-quality finishes.

Future Trends in Subtractive Manufacturing

As technology advances, subtractive manufacturing continues to evolve. Integration with CAD/CAM software enables faster design-to-production cycles. Hybrid manufacturing, which combines additive and subtractive methods, is gaining traction, offering the best of both worlds. Additionally, automation and AI are further improving efficiency and precision.

Conclusion

Subtractive manufacturing remains a vital method for producing high-quality components. Whether it’s CNC machining or traditional turning, this process ensures precision, versatility, and reliability. As industries continue to demand higher standards, subtractive manufacturing’s role will only grow, blending seamlessly with emerging technologies to meet future challenges.

Understanding subtractive manufacturing’s fundamentals can help you make informed decisions, whether you’re designing a product or exploring career opportunities in manufacturing. With its proven reliability and adaptability, subtractive manufacturing is here to stay.