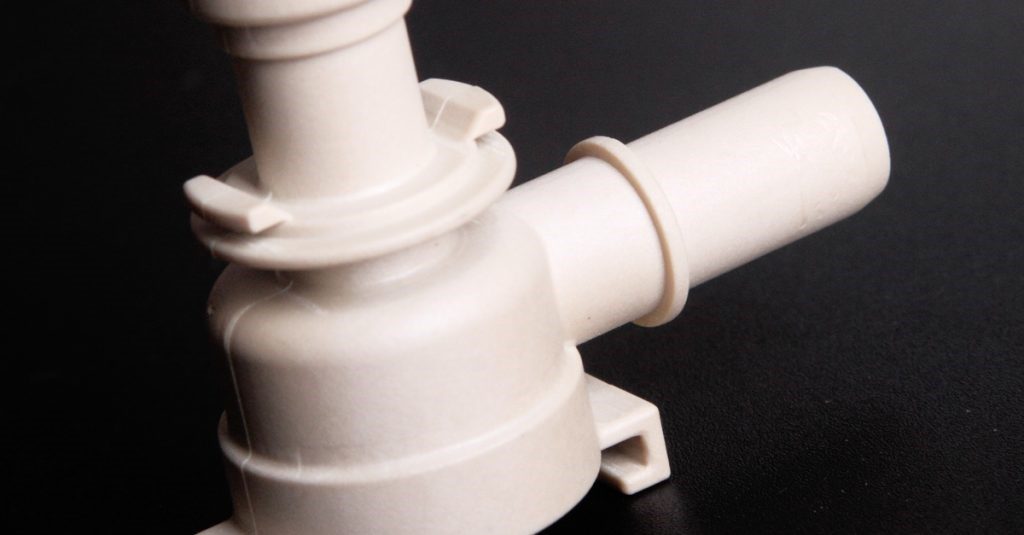

The Rise of Plastic Injection Molding Manufacturing in China

The technological advancements in plastic injection molding in China are benefiting more industries than ever before, and here at HLH Prototypes, we are committed to bringing these innovations to our customers. We can help you manufacture high-quality plastic products quickly and cost-effectively to speed up your time to market and increase your finished product’s adaptability and accuracy.

Keep reading this blog as we share the reasons for the continued rise of plastic injection molding. We’ll also share how our technologies can improve prototyping and end-use manufacturing requirements.

Enhanced connectivity and automation

Enhanced connectivity and automation are transforming the field of plastic injection molding in China. At HLH Prototypes, we keep pace with the latest technological advancements to ensure our molding processes are both efficient and precise. Automation and improved connectivity allow us to meet the unique needs and standards of each customer while offering savings on labor and production costs along the way.

Focusing on sustainability

We work with a wide range of clients from different industries and understand that more businesses are shifting their focus to sustainability and environmentally friendly processes. Our flexibility allows us to adapt to these unique requirements. We can apply eco-friendly manufacturing practices such as minimizing waste and optimizing our operations to reduce energy consumption. In addition, we have access to toxin-free materials, which are especially necessary for the food and pharmaceutical industries. We guarantee these plastics to be non-toxic and FDA-approved.

Reliable, durable molds

HLH Prototypes uses aluminum and steel to create durable molds, with a preference for steel in custom injection molding tools. This choice is based on our experience that steel molds can produce more parts than aluminum molds and offer greater value for low-volume production.

Experience these innovations in plastic injection molding in China by choosing us as your prototyping and end-use manufacturing partner. Call +86 755 8256 9129 or fill out the form for a quote and a free project review.