Watch out for thin walls – CNC machining design TIP

October 23, 2018

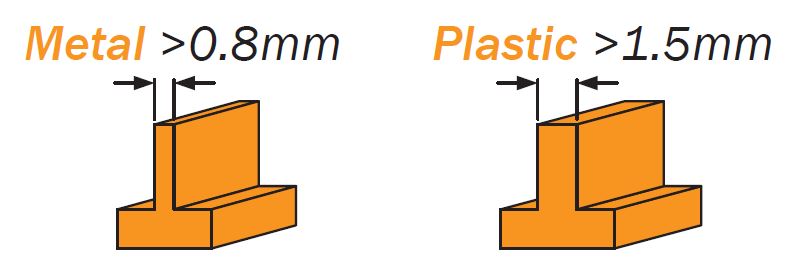

There are a lot of CNC machining design tips to share with you. One common design issue that we see a lot of are walls that are designed too thin. With CNC machining, if your walls are designed too thin you risk warping and affecting the overall accuracy of the part. HLH recommends keeping walls for metal parts > 0.8mm and walls for plastic parts > 1.5mm.

Follow this design tip and others coming up for a part design that is well suited for CNC machining. Below is some further CNC machining guidance which may help you with designing a successful part for CNC machining.

HLH Max CNC Machining Size: 3000x1200x850mm

Advantages

High speed

High dimensional accuracy

Great surface finish

Wide material selection

High volumes

Rapid prototypes

Drawbacks

It can be expensive for complex

parts and for larger parts.

Tolerances – ISO 2768-1 states the tightest tolerances possible as standard are +/- 0.05mm for metals or +/- 0.2mm for plastics. Tighter tolerances should be discussed case by case.

Surface Finishes

Polishing

Sand blasting

Painting

Plating & More

Popular Materials

Plastic ABS, PC, Acrylic

Metal SS304, 316

Aluminium 6061, 7075

Plus many more

Tips and Tricks

Radius internal corners

Loosen tolerances where possible

Keep features perpendicular to the six sides

Reduce the number of setups

Keep it simple