Water Jet Cutting vs. Laser Cutting in CNC Machining

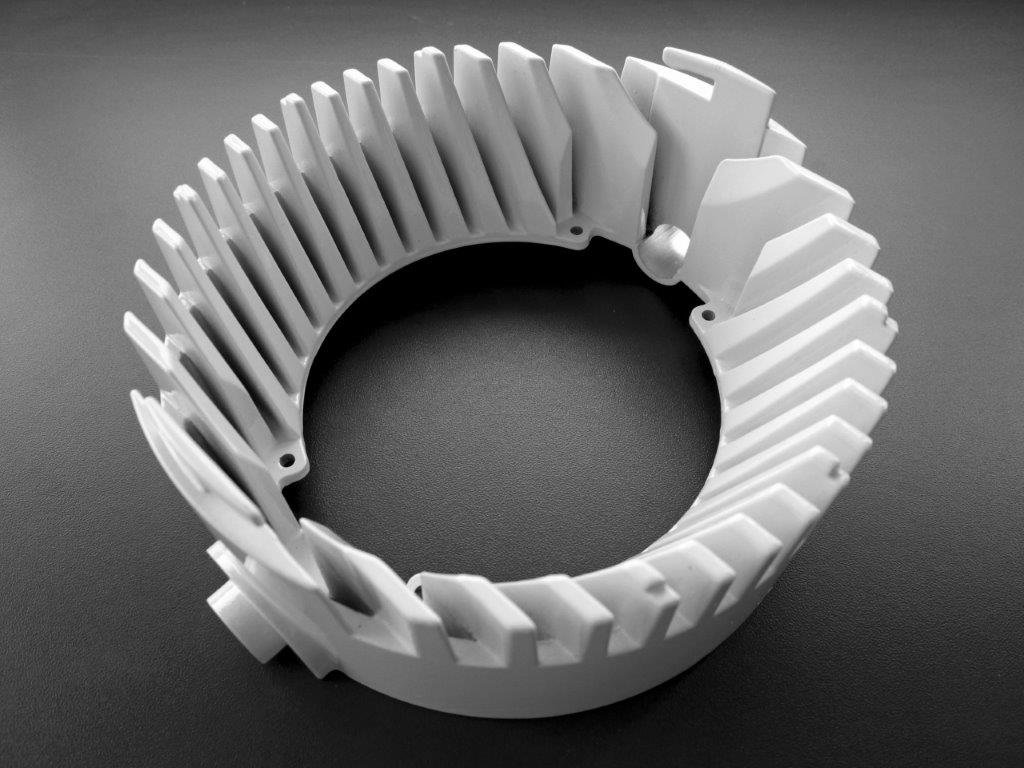

When it comes to CNC machining services, various technologies like water jet cutting and laser cutting are available to bring product designs to life. These subtractive manufacturing techniques are crucial for both end-use production and rapid prototyping. While both have their unique capabilities, understanding the differences between them is essential for choosing the right technology for your specific application. With the appropriate CNC machining solution, it’s possible to achieve precise, high-quality, and durable parts in both metal and plastic.

Exploring water jet cutting

Water jet cutting involves using highly pressurized water directed at a focused point to cut materials. This pressure can reach up to 60,000 psi (or 4137 bar), depending on the project’s requirements. In some cases, abrasive agents are added to the water to enhance the cutting capabilities. This is particularly useful for projects requiring tight tolerances and multiple materials. Water jet cutting is a versatile method in CNC machining services, offering a broad range of cutting possibilities.

Water jet cutting versus laser cutting

While both water jet cutting and laser cutting are capable of slicing through materials, laser cutting also offers the ability to engrave. This engraving feature can be crucial in CNC machining services for projects that need assembly marks, specific aesthetic designs, or serial numbers. However, laser cutting does not support 3D material cutting. Water jet cutting can achieve this to a certain extent, but it is not primarily designed for 3D cutting.

Both techniques have limitations with mixed materials, particularly those with varying melting points. Water jet cutting may lead to delamination, whereas laser cutting could deteriorate the material. Despite these challenges, both methods can cut a wide range of materials. Laser cutting is effective with various plastics and metals, except for reflective ones. Water jet cutting, on the other hand, is applicable to almost all materials.

Finding the right CNC machining technology

HLH Prototypes offers a comprehensive range of CNC machining services, including the latest in water jet and laser cutting technologies. These solutions are designed to deliver parts swiftly and cost-effectively.

Whether your project requires prototyping or end-use manufacturing, consider requesting a quote and a project review from HLH Prototypes. Our expertise in CNC machining services can guide you in selecting the most beneficial technology for your specific needs.