Start making today - get in touch for free quote and project review

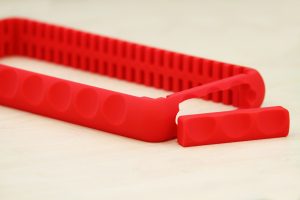

Urethane Casting and Vacuum Casting

Vacuum casting or cast urethanes is a perfect for producing quality parts, without the cost or lead time required for production tooling. At HLH we can vacuum cast large or small items, everything from headphones all the way up to 2m long car bumpers. We have a massive range of materials & services available. Please contact us today to find out more.

How It Works (3 Stages)

Master model – CNC machined or 3D printed via SLA or SLS

Silicone tool – liquid silicone is poured around the master model and cured. Once dry the master is cut from the mold to leave the cavity

Castings – the resin is poured into the cavity to create a production like replica

Contact us to find out more about our Vacuum Casting Services today.

Testimonials

Advantages of Vacuum and Urethane Casting

- Great for low volumes

- Self-coloured parts

- Low upfront investment

- Production like parts

- Massive range of materials

- Rubber like parts and over molds

What is vacuum casting used for?

Low volume prototypes, low volume production, rubber parts, market testing, rapid iterations

Start Your Free Project Review

Vacuum Casting Tips

Vacuum casting enables you to quickly recreate tens of parts in production like materials allowing you to create multiple reproductions of a part for market or in-house testing. There are a number of things you can do when designing your part to ensure it is a good fit for vacuum casting.

Wall thickness is one. As with injection molding you want consistency as far as possible and don’t want to design overly thick sections which might cause sink.

To learn more talk to our Cast Urethane Parts (vacuum casting) team today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...