Rapid Prototyping & Manufacturing for the Telecommunications Industry

The communications industry is everywhere, and we rely on it evermore throughout our daily lives. With the emergence of IoT and smart devices the depth to which it impacts our lives grows even deeper. We work with some of the leading names in the source technologies and their applications to produce prototypes and products to connect the world.

Our massive range of customer focused services allow you to iterate rapidly and offer customised solutions to your clients fast.

We understand the demands and ever changing landscape of the communications industry and work with you to ensure they are met and exceeded.

What is Telecom Rapid Prototyping and Manufacturing?

Telecom Rapid Prototyping and Manufacturing refers to the accelerated processes used in the telecommunications industry for the design, prototyping, and production of hardware and systems. This approach emphasizes speed and efficiency, allowing telecom companies to quickly respond to market demands, technological advancements, and customer needs.

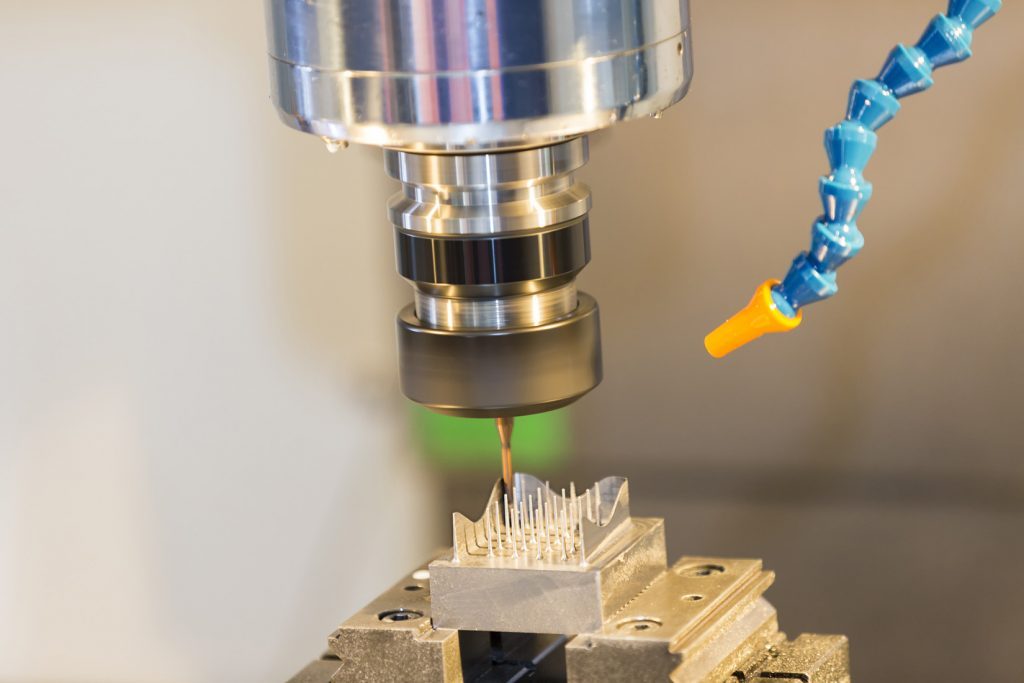

- Rapid Prototyping: This involves the use of advanced techniques like 3D printing, CNC machining, and other forms of digital fabrication to quickly create models or functional parts of telecommunications equipment. This process enables designers and engineers to quickly iterate designs, test functionalities, and refine systems before mass production.

- Manufacturing Technologies: The manufacturing aspect involves the use of automated and advanced manufacturing techniques. These may include robotics, AI-driven processes, and precision engineering to ensure high-quality production at a faster pace. The goal is to reduce time-to-market for new products and adapt quickly to changes in technology or consumer preferences.

- Integration with Design and Development: Rapid prototyping and manufacturing are closely integrated with the design and development phases in telecom. This integration ensures that any design changes can be quickly implemented in the prototype and manufacturing stages, reducing the overall development time and cost.

- Customization and Scalability: This approach supports customization, allowing telecom companies to tailor products to specific market needs or individual customer requirements. It also offers scalability, enabling the swift ramp-up of production volumes to meet market demand.

- Impact on Telecom Industry: In the fast-paced telecom industry, where technological advancements are constant, rapid prototyping and manufacturing provide a significant competitive advantage. They allow for quicker deployment of new technologies, such as 5G networks and IoT devices, and help companies stay ahead in innovation and market presence.

Testimonials

Rapid Prototyping for Telecommunications Common Applications

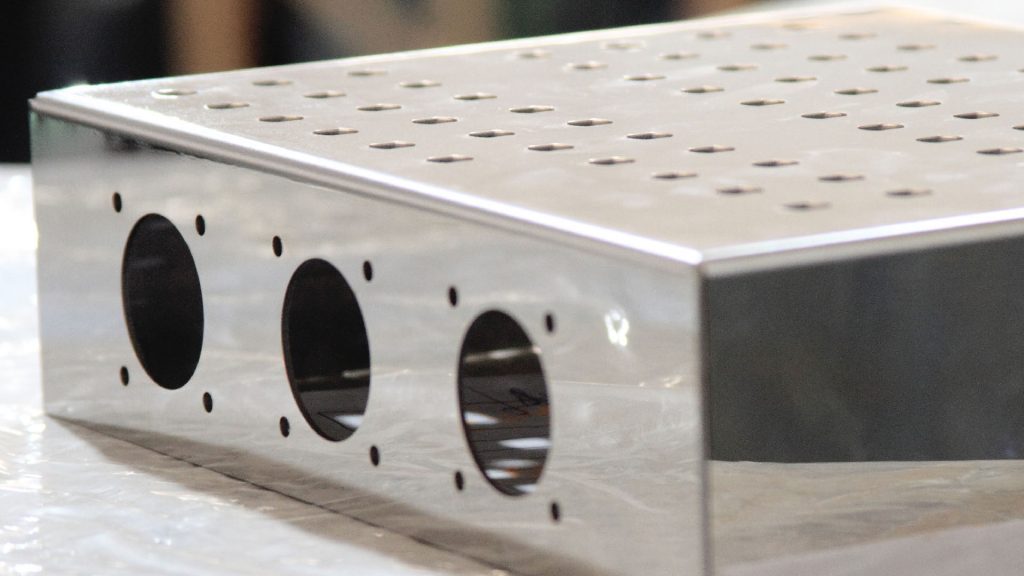

Housings and enclosures, precision parts and prototypes, low volume production, smart devices

Capabilities

At HLH, we produce prototype and low-volume rapid parts for clients in the field of communications via CNC machining, 3D printing, rapid injection molding, die casting, sheet metal, vacuum casting (urethane casting), and more

Rapid Prototyping & Manufacturing for the Telecommunications Industry Tips

For communications projects materials and quality are everything. How can HLH help you connect the world?

CNC machining: precision machined components and metal housings

Rapid injection molding: low volume, high-quality plastic housing, and enclosures

To start your free project review email HLH today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With HLH “We started our cooperation with HLH because we needed a partner which...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by which parts are manufactured by injecting material under pressure into a mold...