Start making today - get in touch for free quote and project review

Rapid Injection Molding

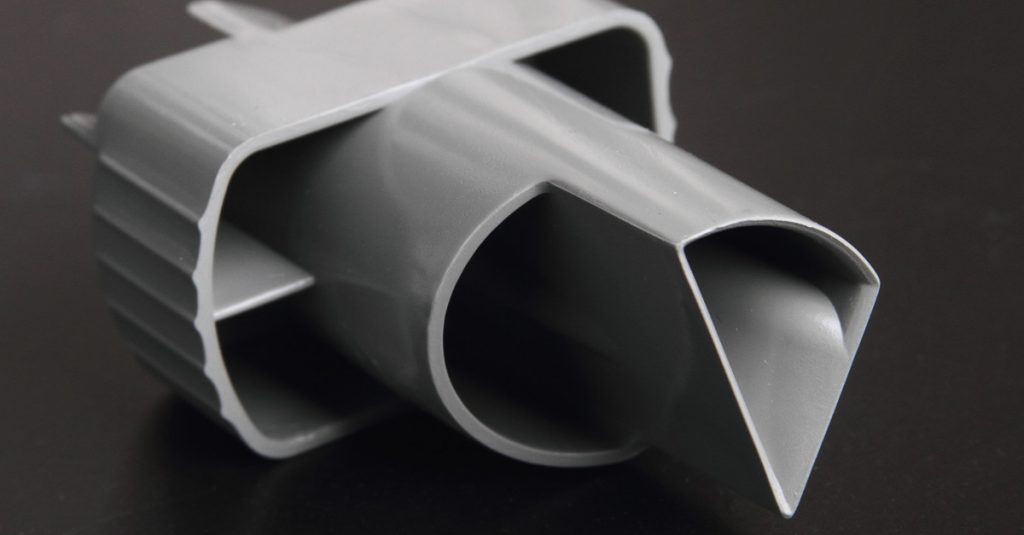

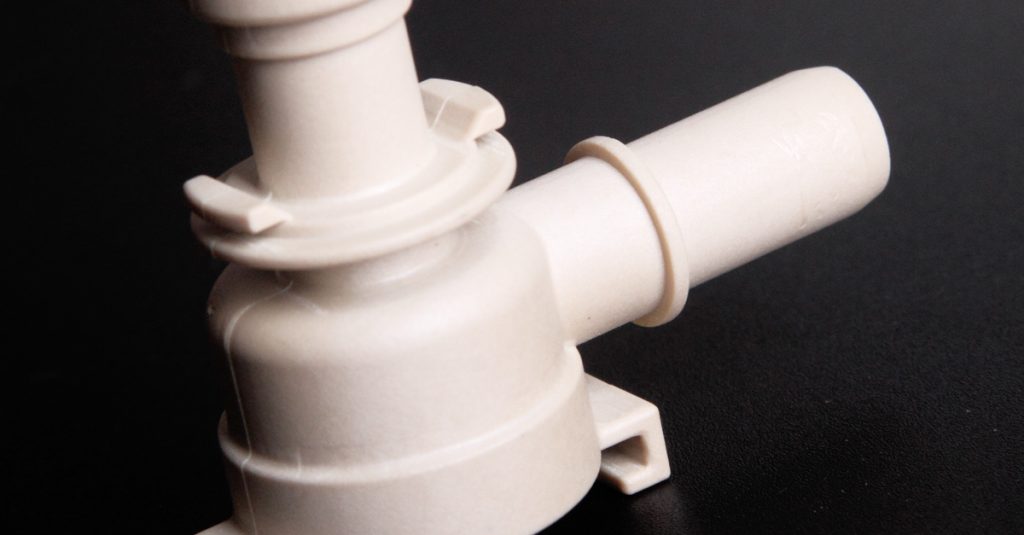

Injection Moulding & rapid prototyping can also come in the form of injection molded parts. How? Rapid tooling (bridge tooling) delivers low volume production quality parts (up to 100,000) from production resins. Think of rapid injection molding as end use prototype manufacturing. End use because your parts are identical to production parts. Prototype because the lead times and costs of rapid injection molding are significantly reduced compared to full production tooling.

Rapid Injection Moulding Services

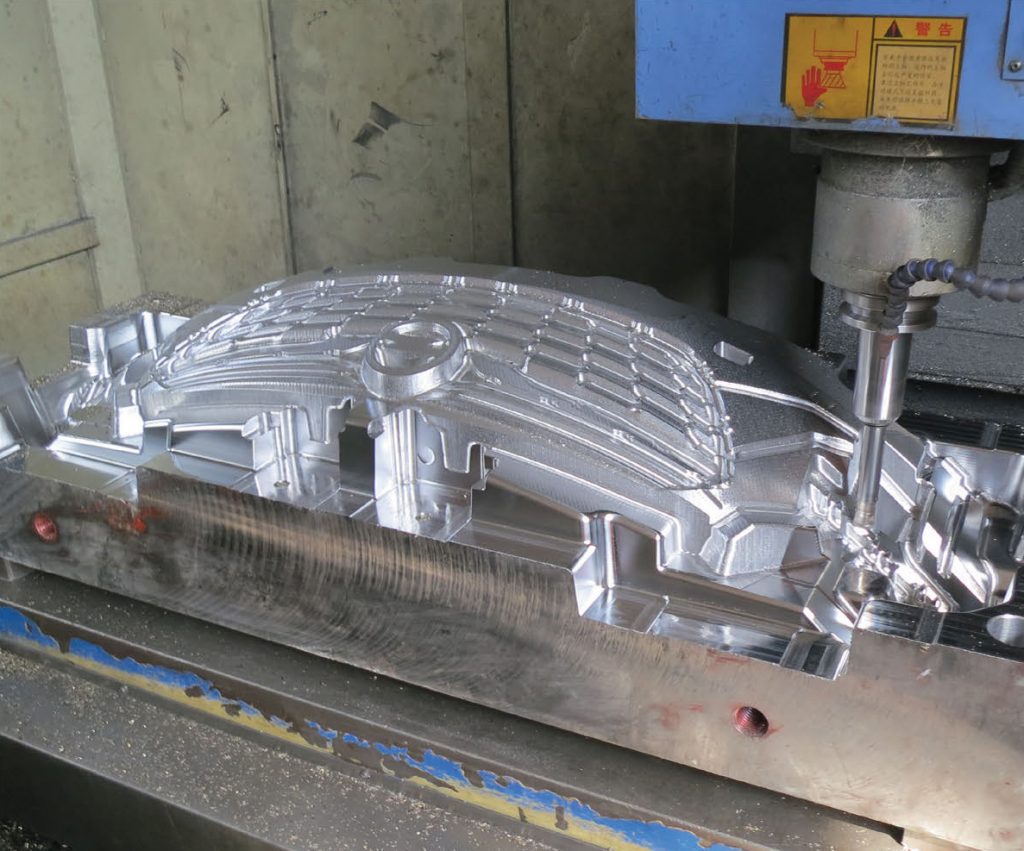

Rapid plastic molding tools are made from steel or aluminium. We use both options but most of our custom injection molding tools are steel. Why? More value for you. Our steel rapid tool injection molding services will typically deliver more than double the parts than comparable aluminium programs.

To start your free project review talk to our rapid injection molding team today.

Testimonials

Rapid Injection Molding Services Advantages

- Lower upfront investment

- Flexibility

- Real production grade materials

- High quality

- High speed

What is Rapid Injection Moulding used for?

Prototypes from real materials, bridge between prototype and production, low volume production, market testing, rapid parts

Follow us on Facebook or LinkedIn for daily tips, advice, trends, and opinions on rapid manufacturing. For fast parts, click below to start.

Start Your Free Project Review

Rapid Injection Moulding Tips

All projects and manufacturing processes come with their own challenges to and guidelines for success. For rapid prototyping there are a number of things you can do to reduce the cost and lead time.

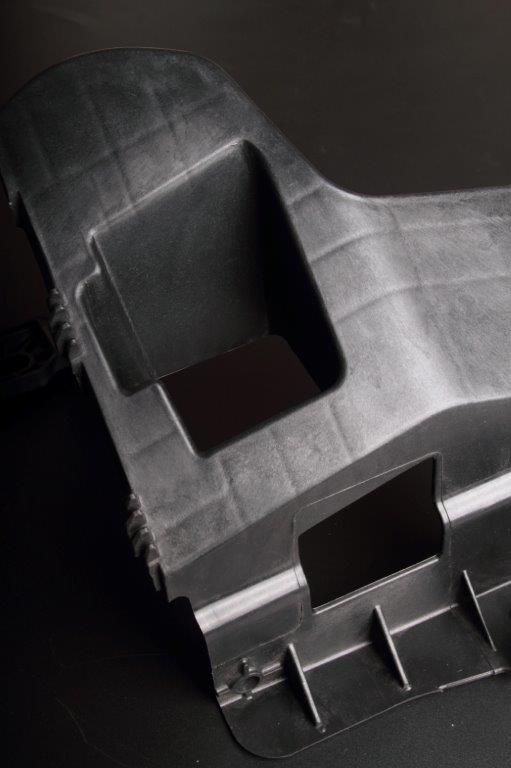

Surface finish is one.

The less processing we need to do to the tool to achieve your desired surface finish the quicker and cheaper it will be. We suggest a SPI Finish B-1 600 Grit Paper as far as possible.

To learn more talk to our rapid CNC manufacturing team today.

Smartfllyer’s SXF1 Hybrid-Electric Aircraft

Case Study

Smartflyer Advances Hybrid-Electric Flight With...

Process Selection Insight 1

Design Guide

What is Injection Molding?

Blog

Injection molding is a process by...